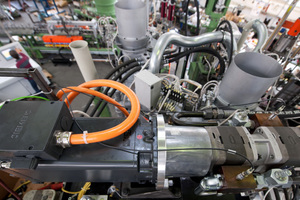

Servo pumps for hydraulic processes enable flexible, compact and energy-efficient solutions

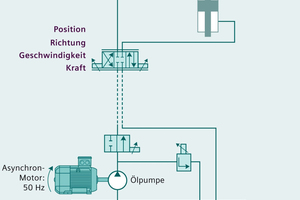

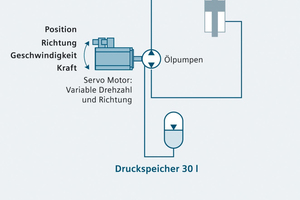

Even in the hydraulic processes of the ceramics industry, frequency-converter-based servo pumps can show their strengths to the full. After all, the innovative hydraulic solutions only deliver power when it is actually needed – thus minimizing waste heat, noise, and wear.

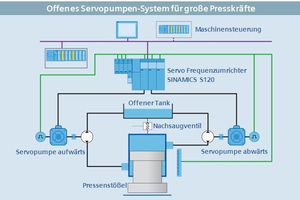

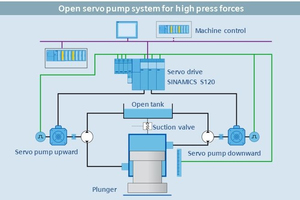

In the ceramics industry, hydraulic presses are among the big energy consumers because hydraulic pumps usually run here at constant speed, even though the power of the hydraulic system is only required at specific points. The energy requirements of a hydraulic press can be reduced by more than 50 %, depending on the requirement profile, by converting the hydraulics to a servo pump system, a combination of pump, motor and frequency converter. The reason is that the motor only runs when hydraulic power is actually needed. In this way, the plant can also be made more flexible, throughput can be...