Vacuum systems in the ceramic industry

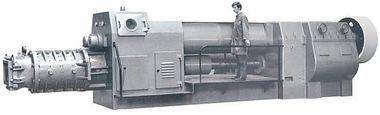

Vacuum is a major component in the processing of ceramic bodies. Particularly in mixers and extruders, vacuum technology enables degasification of clay compounds, hence precluding air inclusions at the pressing/extrusion stage and therefore guaranteeing nearly pore-free shaped products. This also substantially improves their dimensional stability, avoids deformation prior to drying and assures precision dimensional accuracy of the finished products.

For decades now, type-R 5 and once-through (Huckepack) oil-lubricated rotary vane vacuum pumps by Busch Vakuumpumpen und Systeme have been in deployment for such applications. Now, Busch has introduced a whole new clay degassing system called Cobra, which was designed in close cooperation with a Wienerberger brick plant. The core component of this vacuum system is its dry-running rotary vane vacuum pump – also called Cobra. It compresses aspirated air and water vapour with no oil or water. The system comes complete with filter, water cooling and control system and is available in two sizes. This presentation deals explicitly with this new vacuum-degassing technology and compares it with other principles of vacuum generation.

Thomas Meyer,

Dr.-Ing. K. Busch GmbH