Setting and calibration unit for refractory bricks

Bernd Münstermann GmbH & Co. KG is currently realizing a challenging project with a high degree of automation for RHI AG, that is a setting and calibration system for refractory bricks.

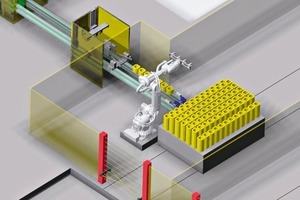

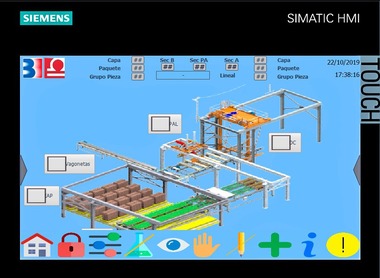

A kiln car loaded with bricks is moved into position. After that, different shapes and sizes of bricks are placed onto a chain conveyor belt by a 6-axis robot, which can be fitted with different types of grippers. Finally, the bricks are positioned for measuring and calibration, the product type is designated and the bricks are measured. At the next position the product is labelled. In the last steps of the process, the products are palletized and made ready for despatch.

The project comprises the following functions:

Unloading of the refractory bricks from the kiln car and positioning of the bricks on the linear conveyor

Calibration (height measurement), marking (grade of classification, designation etc.) and labelling of the bricks

Palletization of the bricks according to grade of classification on wooden pallets

Approximately 60 different shapes and sizes of bricks can be handled with the system. For this reason the content of control technology is very high. An example of this is the specially programmed setting pattern generator. With this function, the operator can adjust the setting pattern to the different brick sizes at the flick of a switch. The robots ensure optimal stacking of the bricks on the conveyors and pallets.

Commissioning of the unit at the RHI site in Mainzlar is scheduled for mid-2016.

Bernd Münstermann GmbH & Co. KG

www.muenstermann.com