Steam helps brick plant dry faster

Company management and the responsible chief operating officer Marco Zanni have decided to adapt their present range of water-struck bricks to the market‘s latest quality standards. With that, the company is reacting to a perceived trend toward smoother finishes, even for good old rustic-type bricks.

In terms of production technology, the company considers itself well prepared: with the help of steam, the mechanical soft-mud moulding process now turns out somewhat less rough-looking textures, and the faces appear smoother overall.

Having collected lots of experience in Denmark on how to increase the product quality of bricks with the aid of high-speed steam generators, Marco Zanni explains: “We deliberately wanted to set ourselves apart in style from our competitors‘ dull, run-of-the-mill assortments.“

Rustic look for an elegant impression

With a certain orientation on Danish models, the smoother faces of water-struck bricks by Janinhoff meet an optical criterion that distinguishes them from their competitors‘ regular-market products. “We wanted a well-defined drip ledge along the top rim of the brick“, Zanni adds. “It makes the overall appearance of the brickwork somewhat more harmonious and elegant – especially for long bricks.“

For extruded products, too, Zanni believes that applying steam is a good idea, since experience shows that preheating the material improves the dimensional accuracy of the manufacturing process.

In Germany, the use of steam generators in brick production is not quite as popular as it is in Nordic countries, for example. In Germany, the production of water-struck bricks is frequently based on the assumption that applying steam to a particularly rough surface structure would damage the visible edging. Zanni takes a different view, i.e., he believes that steam is indispensable for plasticizing and preheating the material.

Fast steam generator reduces drying time

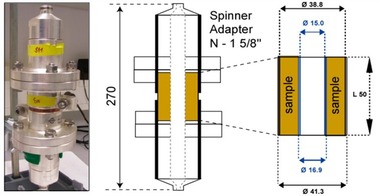

Company management decided in favour of a vertical-type Clayton Steam Master generator.

Marco Zanni, having worked with various suppliers of such systems in Denmark, already had a wealth of pertinent experience.

Janinhoff now rolls the material to the required grain size (down to 0.8 mm) and stores it for later use. During the winter months, the water-soaked material can repeatedly freeze and thaw. Later, when the material enters production at the circular screen feeder, steam is applied to it just before pressing in order to increase its plasticity and keep it from sticking and tearing.

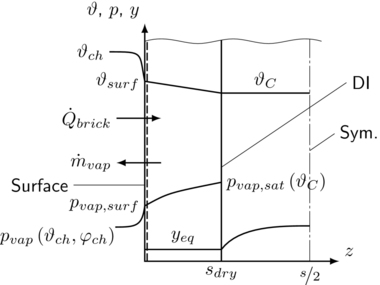

Another advantage of steaming is that the water content of the material can be reduced by 3 to 4%, with an immediate impact on the subsequent drying process.

“The use of steam is a prerequisite for drying the bricks faster“, says Marco Zanni. “Also, the preheating effect of steam addition has a positive effect on our energy balance. Now, the material already has a temperature of 35° C when it enters the dryer. The time saved by that fact alone averages out to one drying day per week.“

While Janinhoff is still drying at a speed of 1 m/s, a planned conversion of the dryers to turbulent drying instead of linear drying is expected to accelerate the drying speed up to 8 to 10 m/s. By expediting the entire preparation and drying process, Janinhoff aims to produce enough material in five days‘ time for operating the kiln at full capacity for a whole seven-day week.

The new gas-powered Clayton Steam Master CSM45 high-speed steam generator has already reduced Janinhoff‘s drying time by 20%. Zanni expects the impending trial period this winter to yield 25% savings on drying time. He remembers a number of sufficiently hard winters in Denmark, when steam had to be used for eliminating ice crystals. Janinhoff is well prepared for such cases and would be able to continue production with no interruption under similar conditions.

Janinhoff‘s Steam Master CSM45 delivers between 175 and 703 kg steam per hour. Commenting on the new addition, Zanni notes: “For our shop-floor employees, its simplicity of operation is a real blessing. The displayed information is easy to understand, and the steam becomes available within five minutes. Moreover, the system is surprisingly compact in relation to our space available and can stay in operation unattended for three days in a row.“

Janinhoff GmbH & Co. KG

www.janinhoff.de