Sustainable alternative to steam-treated clinker bricks

There is an enormously high demand for grey bricks both in private housing and in commercial construction. But unfortunately, the manufacturing process is quite elaborate, requiring firing of the material twice. Moreover, capacity-related bottlenecks have to be expected for this product at present. The Deppe Backstein-Keramik brick manufacturer based in Uelsen has made it its business to meet the demand while not losing sight of the aspect of sustainability. During the last few months, the company was intensively working on the development of a product providing the aesthetic advantages and the colour range of steam-treated bricks but can be produced in a more sustainable and faster manner. The outcome is the P-Line. Only fired once instead of twice, facing bricks of the P-Line can be manufactured in a wide variety of colours, while being characterised by a considerably simplified and less energy-intensive manufacturing process and a better brick quality.

Status quo: Steam-treated material

The steaming that is necessary for the production of grey or similarly coloured bricks requires two firing processes. For technical reasons, these processes can only take place at different sites using specific kiln systems. Owing to double transport routes, twice the amount of packaging material and two firing processes, for one thing, steam-treated facing bricks are cost-intensive and, for another thing, a lot of energy is consumed in their production process. Last but not least, concessions in quality, e.g., concerning the water absorption have to be made in case of steam-treated material.

New range of colours along with reduced energy consumption

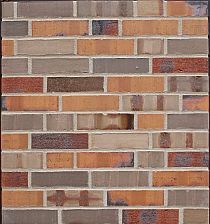

The waterstruck brick of the P-Line consists of heavy clay raw material and is processed together with special components. Just one firing process in the kiln is sufficient for obtaining the interplay of colours of a steam-treated facing brick. As a consequence, double transport routes and double transport packaging are omitted completely; the energy consumption is significantly reduced by just one firing process. And there are virtually no limits on the range of colours: From grey-green to blue through to orange everything is possible. In this way, even the firing of colours is possible that could not be achieved at all previously. The clay is integrally coloured after only one firing procedure and nevertheless getting the look of a steam-treated brick. The clinker bricks consist to 100 % of ecological starting materials, feature a long service life and allow for recycling as well as downcycling at the end of the first use.