Tenax Energy Saving

Since 1991 Latermec has been operating in the Italian and international market. The area of specialization is given by the supply and regeneration of spare parts of the extruder and dies.

Latermec’s main guiding values are tradition and innovation, according to the company. The experience and the know-how accumulated in time allowed the company to propose to the customers the Tenax Energy Saving – according to Latermec a unique system of surface treatment.

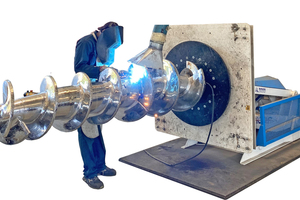

At the core of this treatment, Latermec has the highly suited to each other combination of wear-proof welding with carbides of chrome complex type and galvanic hard chroming. This combination reaches a hardness degree of 75 HRC.

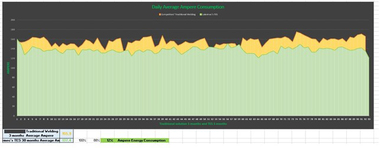

The clients which have used a full set of extruder augers with TES treatment have gained significant improvements in terms of: reducing extrusion pressure (Bar); reducing the temperature inside the extruder head (°C) where usually it reaches exaggerated values; easing the functioning of the extruder due to lower friction coefficient and reducing the extruder energy consumption up 15 %.