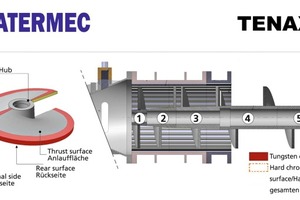

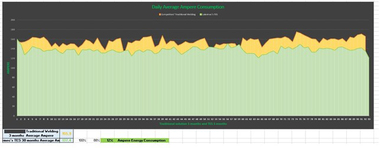

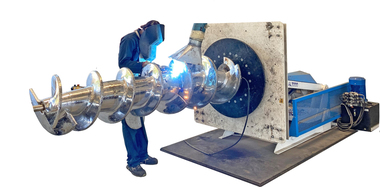

In modern industry, engineered hard chroming fulfils purposes in a wide range of applications that are difficult to achieve with conventional materials. Brick manufacturers effectively use this process to enhance their equipment with chrome properties, for example surface hardness of 70 HRC and a coefficient of friction of 0.12. These features provide superior abrasion and wear resistance while the reduced friction can also bring a considerable reduction in power consumption, especially when chrome plating is applied to propellers and screw conveyors.

Latermec has been successfully operating in the brick and ceramic market since 1991, offering a comprehensive hard chrome plating service. For the most demanding uses, Latermec also offers Tenax wear-proof coatings made of tungsten/chromium carbide and ceramic.