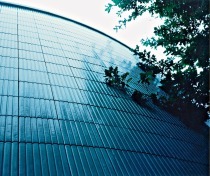

U-bricks – for sophisticated architecture with barely perceptible joints

Each U-brick has narrow, roughly ten millimetre-high rims at front and rear. This shape enables installation of clinker façades with minimal joint widths of about 4 mm. The bricks also have recesses for mortar at each end. Since the vertical joints are filled with mortar, the façade is impervious to driving rain.

U-bricks can be handled and laid in the same manner as conventional bricks, and thanks to their front and rear rims, either side can serve as the face. The mason can apply the usual twelve-millimetre layer of mortar, but since all the mortar is hidden inside, the wall is uninterruptedly ceramic in appearance. Easy size adjustment facilitates execution of a thoroughly uniform façade. U-bricks can be placed flat and untilted using traditional tools. All the mason has to do is apply the proper amount of mortar to keep it from oozing out between the bricks. Consequently, there is practically no need for touching up the finished face. Likewise, this also prevents mortar from welling out into the space between the clinker façade and the thermal insulation. Otherwise, thermal bridges could form in the masonry shell. Nor do U-bricks require any particular anchorage or reinforcements. Only the usual materials are needed.

Compared with conventional masonry, U-bricks require less mortar. Also, hardly any excess mortar has to be raked out, so the joints need no pointing, and the finished façade does not have to be scrubbed down. And soon as the last brick is in place, the façade is finished and the scaffolding can go. This technique is especially efficient and thrifty.