Ultralite finds favour with heavy clay makers

One of the benefits immediately evident is Ultralite’s ability to trap air, leading to exceptional insulation characteristics. There is a high proportion of air open space within the structure, meaning a low solid density. Consequently, the heat transfer through the material at elevated temperatures is significantly less than that of traditional insulation materials, such as firebrick and ceramic fibre. All of this leads to tangible energy savings. Ultralite is a stable product and, although free flowing, maintains good shape and offers a longer lifecycle.

Ultralite helps overcome several problems encountered in the brick industry: The first of these is where, in a traditionally set up kiln car, the setting sand (or “placing sand”) gradually drops down between the cracks of the decking tiles and, having nowhere else to go, ends up gathering between the tiles and also in spaces in the vermiculite castable often used in this sector. In the worst case this can drive the tiles apart so that the kiln car gets wider and wider. The only way to prevent this is to disassemble the top of the kiln car, clear away the sand debris, replace the insulation and then reassemble. Furthermore, any ceramic fibre has to be disposed of in controlled conditions. Across an entire operation, this involves a great deal of costly maintenance and unwanted down time.

“When we demonstrated to one of the world’s leading brickmakers how we could help in this area of the kiln, they started a switch to a new system”, said Ultralite’s Sales and Marketing Director, Paul Hipkiss. “Now there are reconstructed kiln cars which dispense with ceramic fibre and, instead, rely on a castable layer at the base on top of which is poured the Ultralite ROK loose fill insulation. This is topped off with 65-mm deck tiles in the normal way. It has led to a far more thermally efficient tunnel kiln operation.”

Another consequence of Ultralite’s thermal superiority is a noticeable reduction in undercar temperatures – typically from as high as 150° C down to less than 80° C. One advantage is much less maintenance required on kiln car wheel bearings. Ultralite’s main brick industry customer has found that in practice, since switching over to the new material, reduced undercar temperature means the replacement cycle of bearings has been extended from 12 months to 3 years. As can be seen, once again, less work needed and more money saved.

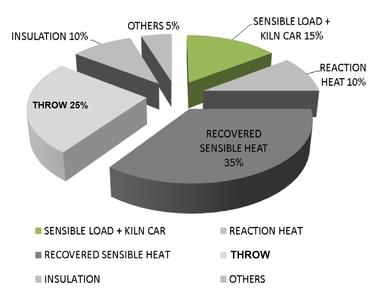

Heat flow calculations have been conducted on this plant and comparisons drawn between the original kiln car construction and the new one featuring Ultralite loose fill material. The results have clearly demonstrated that the heat stored in the kiln car base and the heat-flow through that base is 26% less than previously – another significant energy saving.

Many of the above mentioned advantages are equally applicable when it comes to the safe, stable and fuel efficient firing of pavers, clay blocks and clay roofing tiles. One of Europe’s leading roof tile manufacturers is currently switching over to Ultralite for its kiln cars.