Wienerberger and Sabo – Successful cooperation continues

Following the completion of the modernization project at its Jezernice plant in 2015, Wienerberger contracted Sabo with the modernization of two more plants in the Czech Republic in 2016.

Wienerberger Holice

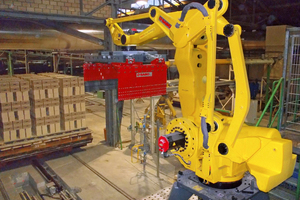

The project involved the modernization of brick dehacking and packaging stations. Sabo replaced the existing conventional grippers for dehacking the bricks from kiln cars and loading them onto pallets with robotized systems. A robot was installed to dehack the bricks from the kiln cars layer by layer. It takes the bricks from the kiln cars and sets them on a new programming bench for preparation of the final layers. The bench is also equipped with a tilting unit. The second robot takes over loading of the pallets with fired products.

Sabo also installed a complete chain conveyor system for empty as well for full pallets. This transports the pallets to the exit where they are picked up by a forklift. The equipment is configured to work with different types of pallet so that the plant has a range of possibilities for putting together the final packs.

A new transport mechanism was installed for the kiln cars to ensure accurate positioning of the cars at the unloading position.

All the machines were designed to work with all the different products that the plant manufactures. The line is completely ready for the incorporation of a grinding line for blocks at some point in the future.

The project was completed successfully end of March 2016 and met all the capacity and quality targets.

Wienerberger Novosedly

The objective was to modernize the dryer car unloading and the kiln car setting stations. Sabo installed a new chain conveyor for transferring the laths with dry material from the existing unloading elevator. A new robot with double gripper unloads the dry blocks from the laths and sets them down on the programming bench. The existing programming bench has been modified with the addition of a new part to ensure the correct programming of the blocks and to accommodate the installation of a tilting unit in the future.

After programming, the layers of bricks are transferred to the final conveyor bench by means of a pushing system. The new setting robot takes over the loading of the bricks onto the kiln cars. The flexibility of the robot enables it to realize different setting patterns and handle the entire range of products manufactured. The kiln car is kept at the exact loading position by a centring system, ensuring stable positioning of the car during loading.

In addition, a new gripper was installed for feeding the empty laths to the wet side or storing the empty laths in the storage area.

Besides the installation of new equipment, modernization of the existing equipment was also part of the project. Sabo also supplied new electric boards and programming of the whole dry side and dryer car drive, ensuring the efficient operation of the production line.

Special attention was given to the design of the access platforms around the machines and the placement of the protective fences.

This project was also completed successfully end of March 2016 and met all the capacity and quality targets.

ZZ Wancor, Istighofen, Switzerland

Following the excellent cooperation between Sabo and ZZ Wancor on a previous project in Istighofen completed in 2014, ZZ Wancor contracted Sabo with a new modernization project in Istighofen plant for 2015.

The project involves modifications on the wet side to enable the plant to introduce new products in production. Sabo installed new machines and made the necessary modifications to the existing machines for handling the wet bricks downstream of the cutting line. A new gripper for wet bricks with two heads for the existing robot was designed and installed.

At the setting station new grippers for the robots were installed to work with the new products.

At the dehacking station, Sabo installed a new robot for dehacking the products from the kiln cars layer by layer. Having been unloaded from the kiln cars, the bricks travel on new belt conveyors through the grinding machine.

After grinding, a new conveying system with a pusher and a tilting device to tilt the bricks when required moves the bricks onto the final conveyor belt. Then the existing robot takes the ready layers from the belt and loads the pallets layer by layer.

All production targets have been met and the project successfully delivered.

Sabo S.A.

www.sabo.gr