Reaching the top with innovation, digitalisation and sustainability

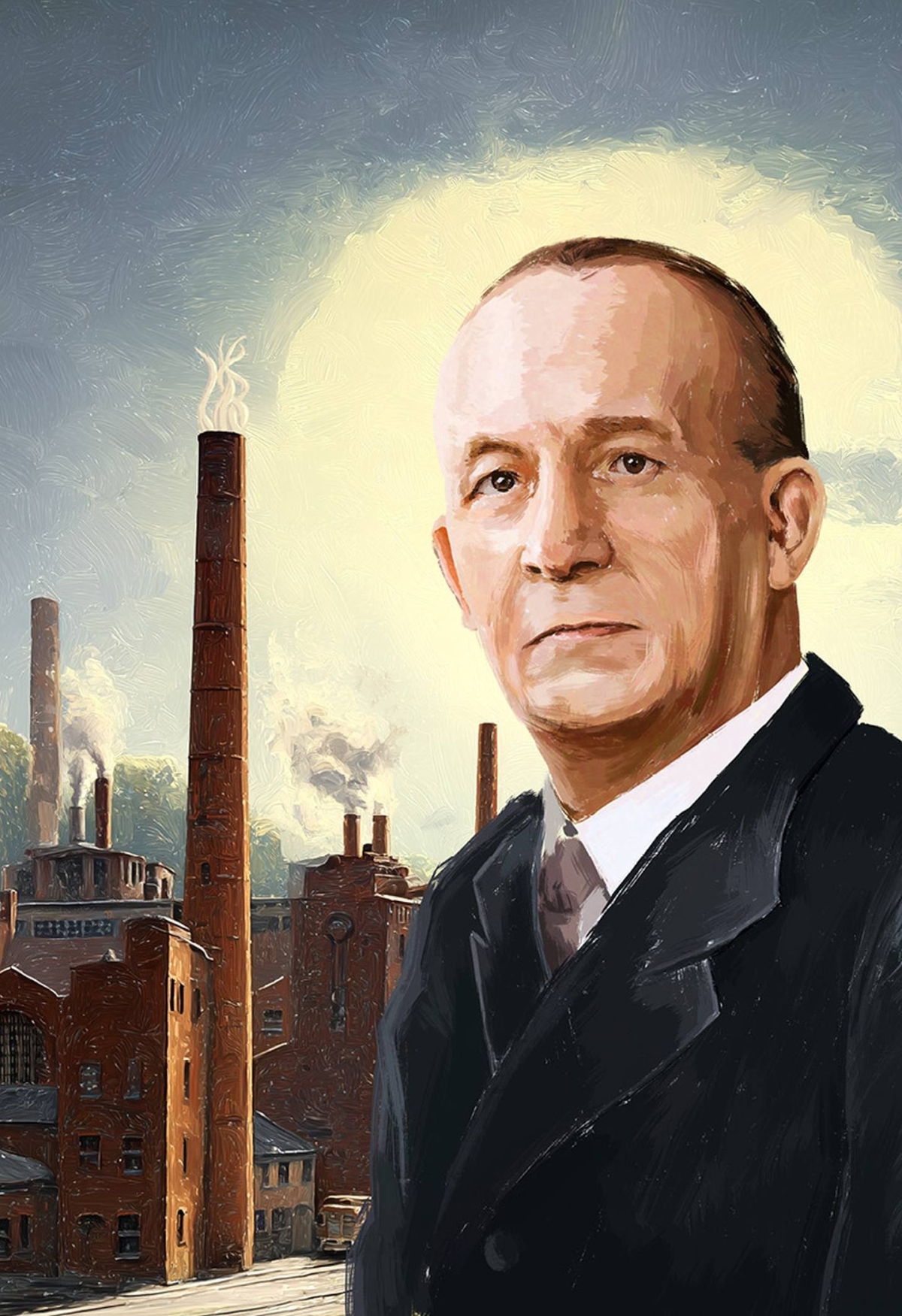

Premium brick manufacturer Vandersanden: interview with new CEO Deburchgrave 02.10.2024Johan Deburchgrave took over the helm at Vandersanden in January 2024. With more than 30 years of experience in the construction industry, Deburchgrave wants to keep the premium brick manufacturer on course for growth. And as the new CEO of Europe's largest family-owned brick manufacturer, he reflects out loud in this interview on his responsibility towards customers, employees, the environment and the construction industry as a whole. His strategy: sustainability, innovation leadership and powerful digitalisation.

Deburchgrave studied civil engineering at the Katholieke Universiteit Leuven (Belgium) and supplemented his management knowledge with an MBA and various management courses at universities across Europe. He intends to use his more than 30 years of experience in the building materials industry, including at Etex Germany Exteriors (the manufacturer of Eternit corrugated sheets), to promote innovation, digitalisation and sustainability at Vandersanden. Deburchgrave sees the greatest current challenge in the highly complex market situation.

Complex market situation

Johan, how do you assess the current market situation?

The great economic uncertainty is making it difficult for consumers to decide where to spend their money. There is great uncertainty due to conflicts in Ukraine and the Middle East, inflation and exorbitantly high energy costs. This has also increased the cost of all building materials. Modernisation projects or new builds are being postponed. Last but not least, the political situation on the German market, for example, is tense, as a wide variety of environmental regulations are not differentiated clearly enough. This is what makes the market so volatile at the moment.

But I am optimistic, also for the German market. The figures from neighbouring countries such as Belgium, the Netherlands and even the United Kingdom are already pointing to an upturn. In our sector in particular, Germany has unfortunately always been a little more sluggish when it comes to economic upturns. But here, too, we can already see a glimmer of light on the horizon.

How do you arrive at this optimistic assessment?

Building has become more expensive overall. You can build less today for the same money as yesterday. Unfortunately, all prices have risen. And now that the situation seems to be normalising again, the public expects prices to fall again. This basic attitude is leading to a wait-and-see attitude among all those who want or even have to build. The renovation sector, on the other hand, is already doing well again. This is because when new construction becomes expensive, the budget spent shifts to the purchase and renovation of existing properties. The number of mortgage loans granted there remains stable.

The current trend in key interest rates also looks quite favourable. At its meeting on 6 June 2024, the ECB lowered its key interest rates for the first time since March 2016. Money is therefore becoming cheaper again, which will almost certainly have an impact on our industry.

So you took up your job as Vandersanden CEO in rather turbulent times...

That's probably true; there is uncertainty everywhere. That's why consumers are still holding back. But I'm sure that things will pick up again soon. Because in the coming years, massive amounts of new homes will have to be built all over Europe to meet the enormous demand. I can see that Vandersanden is already ready to capitalise on these growth opportunities.

Sustainability and innovation

How has Vandersanden prepared itself for the enormous challenges of the future?

We already have the solutions to many of the questions of the future in the drawer. In recent years, Vandersanden has focussed very strongly on innovations in products and processing. I find that admirable, because the construction industry is known for its traditional, cautious approach. In this respect, our new CO2-negative facing bricks Pirrouet®, the climate-adaptive paving clinker DrainFlow® and RoboBrick®, the fully automated bonding of brick slips to prefab parts, are ground-breaking inventions.

While Pirrouet® will drastically reduce the carbon footprint of the entire construction industry, Robobrick® is a solution that will bring huge efficiency gains. The use of RoboBrick® will not only save massive amounts of time compared to traditional construction processes, helping us to address the shortage of skilled labour in the construction industry, but also up to 60% in raw materials and energy. We can use our DrainFlow® permeable pavers to improve water management in cities and even for greening.

Of course, we are also sticking to our "Together to Zero" promise. We need to get our CO2 emissions to zero. Better sooner than later. We are working on this with great vigour. Dematerialisation, renewable energies and the associated conscious use of raw materials and energy are at the top of our roadmap.

And we are investing in solutions for the circular economy, such as dry stacking systems, i.e. walls without mortar. After all, construction waste is one of the biggest problems in our industry. It's absurd, because a house lasts 80 to 100 years on average, but a single facing brick lasts much longer. So you could clad several buildings with the same bricks. And we are currently developing smart solutions that actually make this possible.

So sustainability is purely an end in itself for Vandersanden?

That makes me laugh. Of course not. But I am very inspired by Vandersanden's clear long-term vision and ambition to be a pioneer for sustainability in the entire construction industry. After all, Vandersanden follows up its many fine words with concrete actions. Logically, we have to sell our bricks first and foremost. However, sustainability is now a compelling argument for modern consumers and especially for architects and institutional decision-makers.

The trick at Vandersanden will be to find the right balance between short-term and long-term ideas. In this respect, we are a bit of a victim of our drive for innovation: we think miles ahead, while we have to keep moving forward in terms of customer experience, energy efficiency and dematerialisation, even in the short term. But I've found the team here to be so innovative and committed that I don't really have to worry about that.

So sustainability is still a high priority at Vandersanden?

Absolutely, the transition to CO2 neutrality will be an absolute priority in the coming years. However, we don't see this as a threat at all. We will continue to consistently roll out "Together to Zero" with a clear roadmap and many players in our industry. This will strengthen our position as a climate pioneer and enable us to react quickly to new developments. This will also help sales.

Digitisation

That was a lot of words about Vandersanden hardware. But what about the digital Vandersanden world? Keyword digitalisation.

Vandersanden is constantly working on the digitalisation of its product range. Milestones in recent years have been BrickDrive, for example. BrickDrive increases loading efficiency, speed and safety thanks to the digital pick-up module when collecting our products. The texture generator for façade bricks and paving stones was a novelty that was particularly well received by creative professionals.

And then there is the conversion of our entire IT to a state-of-the-art, integrated system that makes all internal processes leaner, clearer, quantifiable and measurable. When we realise such efficiency treasures, our customers also benefit. And that's what it's all about. The Vandersanden experience as a holistic experience for beautiful façades and paving in the long term. Because digitalisation is not an end in itself at Vandersanden.

Incidentally, the ideas for the processes to be digitalised do not come from nowhere. It's always an impulse from the customer or the team, a brilliant little idea that gets the digitalisation ball rolling. It goes well with this: I firmly believe in a participative work culture; I will listen very carefully to my colleagues' ideas.

So you will listen to your employees in Europe's largest brick-producing family business?

That is exactly my goal. Because when we implement ideas and give these good ideas the recognition they deserve, it has an immediate effect on the mood in the company. And a prosperous company needs a good mood among its employees. Vandersanden has always called this "collective well-being". As part of society, we want to contribute to the well-being of all people. Economic success is a means of making a significant contribution to the well-being of our employees, customers, society and the environment. I am determined to continue along this path with Vandersanden!

Vandersanden, the largest family-run brick manufacturer in Europe

Sustainable production, expertise and innovation in brick production are at the forefront of the Vandersanden family business. Vandersanden offers brick products for the planning and realisation of buildings, gardens, parks and road construction. The "Vandersanden family" consists of over 800 employees in Belgium, the Netherlands, France, Germany and the United Kingdom. With a total of nine production sites for facing bricks and clinker bricks, pavers, brick slips and insulated façade systems, Vandersanden is the largest family-run brick producer in Europe.

Vandersanden also offers fully integrated solutions, such as RoboBrick and Drainflow, to meet today's challenges in the construction sector.

With the sustainability programme Together to Zero, the pledge to produce and operate completely carbon neutral by 2050, the brick manufacturer is reaching out to other stakeholders to work together to become carbon neutral.

Vandersanden produces over 600 million bricks per year for the European market and far beyond. The brick expert is not only the market leader for hand-moulded facing bricks in Belgium and Germany, but also for the paving brick segment in the Netherlands.

The Vandersanden brick production in the Belgian and Dutch plants operates in accordance with the environmental management standard ISO 14001 and the plant in Upper Lusatia in accordance with ISO 50001.

Jaak Vandersanden founded the traditional Vandersanden brickworks in 1925 in Spouwen (Bilzen), Belgium, not far from the German border. The brick manufacturer's headquarters are still located there today.