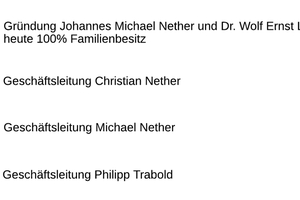

40 years of Thermoplan - a traditional heavy clay ceramics company

In 2022 and 2023, Thermoplan took advantage of the opportunity presented by the changed market parameters to implement an accompanied generational change in management, diversification and, above all, significant growth.

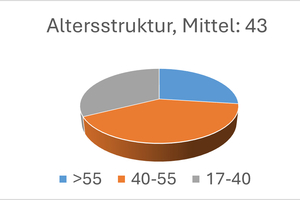

The course set in 2020/21 to significantly increase sales, build up in-house mechanical expertise and production and expand the product portfolio is now bearing lasting fruit. The starting point was 20 employees, by the end of 2023 there were already 35, and the target for the end of 2024 is 50 employees. In addition to the headquarters in Olching, Germany, a second site with mechanical production has been established in Brilon, Germany. The employees of the former Rumke GmbH have been integrated, and the number of employees there has already doubled.

The Thermoplan business strategy of personal customer loyalty and customised solutions, together with extensive experience and knowledge in many areas, including ceramics itself, are the company‘s core competencies. The willingness to dedicate itself to both large and small tasks and to provide good service has been very well received. The integration of many highly experienced employees has ultimately helped to spread this expertise and strategic service orientation across many shoulders and to significantly increase and broaden the company‘s overall expertise.

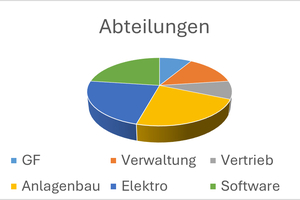

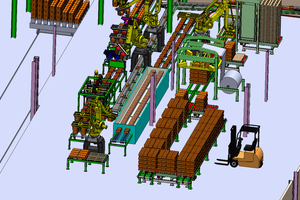

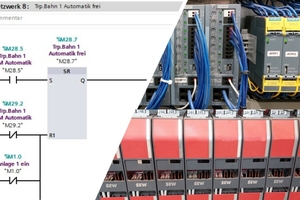

Thermoplan is now available as a contact partner for all areas of a brickworks, regardless of whether raw materials, systems, electrical engineering, process/firing technology, production organisation, quality testing or the areas of data/software/IT are involved. In addition to heavy clay ceramics, this also applies to the areas of fine ceramics, refractories and technical ceramics.

The focus on the Central European market allows a certain concentration of sales activities and should ensure that a stable and successful German plant engineering company will continue to be available in heavy clay ceramics in the future.

In contrast to its market competitors, this much more comprehensive focus in terms of expertise, product portfolio, project sizes and target markets is intended to secure the company‘s future success in the long term and enable further growth despite the declining overall market. Various collaborations with other, more specialised providers have resulted in the ability to provide a suitable answer to every question. In particular, the areas of firing technology and mouthpieces/pressing heads should be mentioned here as new co-operations that are available through our sales department.

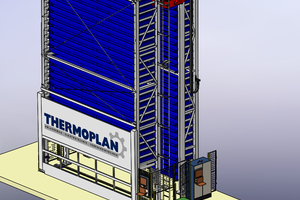

In addition to being firmly anchored in ceramics, we have now succeeded in establishing another stable pillar in the area of storage technology/intralogistics. In addition to service and retrofitting, we have also been able to offer new systems from our own company since 2023. The systems we support are heavy-duty warehouses, high-bay warehouses and storage towers.

Of course, we will be represented at Ceramitec with a large stand, including our latest development, the ‚Bluebox‘ roof tile testing system, and we look forward to celebrating our 40th anniversary together with our customers.