Salamabriq project successfully completed

Salamabriq is designed for a production capacity up to 500 t hollow blocks per day. Regionally available raw materials are used for production of the clay blocks. The clay preparation area starts with a primary crusher, and then is further followed by a 182 DS pan mill and the refining roller mills. The clay body is sent via several box feeders to the clay storage, where it is left to rest and homogenize.

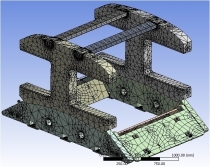

The shaping area is equipped with a hydraulic hinged roller mill model LABH 092/1000, with Ø 1 000 x 1 000 mm roller shells, with a working gap between 0.8 mm and 1 mm.

The extruder is a Verdés Combi model 077C/65 equipped with an elevating platform, enabling adjustment of the height of the extrusion axis according to the different sizes and dimensions of the products to be extruded. This machine is fitted with highly wear-resistant chrome alloy augers with a conical geometry, having Ø 700 mm in the feeding area and Ø 650 mm at the exit.

The first extrusion test was conducted in November 2010. Good production results and the required output were achieved as expected.

Talleres Felipe Verdés thanks the customer for the confidence shown.