Freymatic develops adjustable sets of cutting change parts for multiwire cutters

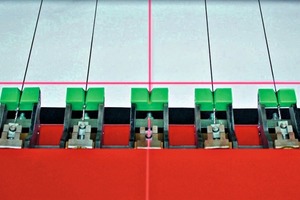

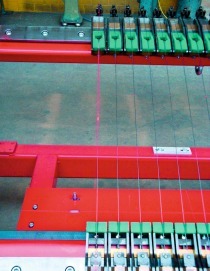

As the wire holders are mounted on a guide rail, the distance between the wires may be freely adjusted. Furthermore, shock-absorbing wire-tensioning units increase the service life of the wires multifold. The cutting tables too are adjustable, and the table plates are designed as change parts with quick-lock.

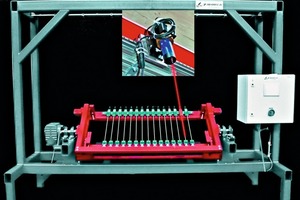

Yet how do you find the true position of wires, tables and plates? For this, Freymatic developed a special adjusting tool on which the cutting change parts may be fixed. The holding fixture for the wire frame (with the chamfering discs) is pivotable, allowing free access to wire holders and chamfering shafts.

Above the setting level, a linear unit with positioning laser moves from one position to the next in order to project the precise position of the tools. The operator must then only fix the wire guides, table plates and chamfering tools in the indicated position, and the cutting change parts are ready for installation in the multiwire cutter.

The programming of the positioning laser consists in setting the requested number of products and cutting length. The laser pointer then resets itself automatically and moves toward the first position.

The idea convincing in the field

This innovation was immediately patented by Freymatic AG, Switzerland. The adjustable cutting change parts are now available and the first orders have already come in.