Raw material analyses for clays, engobes and glazes

The laboratory‘s activities mainly comprise the investigation of raw materials and additives for the ceramic industry, including analysis of clays, opening agents, additives, engobes and glazes. Each year, some 20 000 samples from all over the world are sent in to the Dutch laboratory in Velp. In all, approx. 50 000 analyses are carried out on them.

For particle size distribution measurements, the institute has a fully automated analyser that can handle more than 200 samples of clay a day according to a standard procedure based on a combination of sieve analysis and the Andreasen pipette method. These data, together with information about the specific surface area and the chemical composition, enable prediction of the clay‘s behaviour in terms of mouldability, drying and sintering behaviour. These basic analyses are performed around the clock on demand.

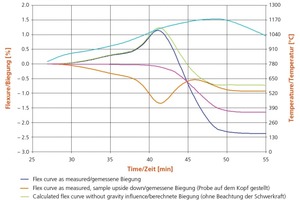

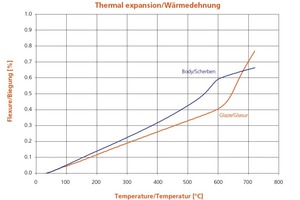

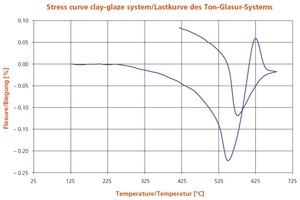

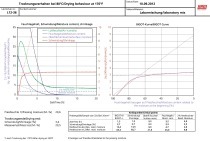

Additional, specific forms of analysis provide insight into the material‘s drying characteristics (Bigot curves, moisture conductivity, pore size distribution, water-soluble salts in the clay, etc.) and sintering behaviour (dilatometry, TGA/DTA and flexure measurements). In combination with the chemical analysis of glazes, engobes and multilayer systems with clay components, contact dilatometric and optical dilatometric/fleximetric tests (»1 and »2) provide specific data on shrinkage behaviour and response to heating/cooling. These tests are particularly important, as they permit evaluation of the bond between the engobe or glaze and the clay body, as illustrated in »3.

The results of all these analyses are subsequently discussed with the client and considered in conjunction with the behaviour of the materials in actual practice. This interactive form of cooperation and feedback gives the client increased insight, makes the production control process more effective, and encourages new developments at the client’s company.