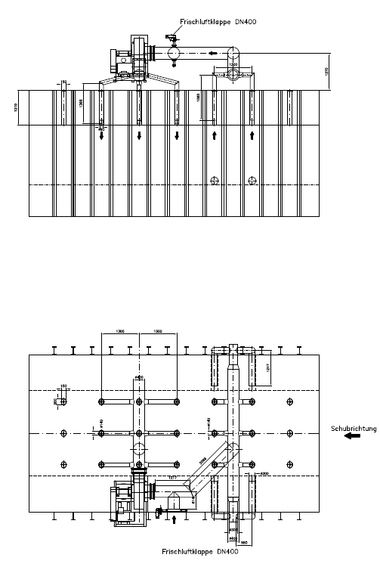

Many brickmaking plants eventually encounter the problem of sand and other material accumulating in the bottom-flue and viaduct blocks, and it all bakes together due to sintering. The resultant adherent layer is often very hard and cannot be removed by such normal means as the extraction system or brushes. GSP, a supplier of handling systems of kiln car cleaning systems, has developed a milling machine for use in removing stubborn crusts from bottom-flue and viaduct blocks.

The bottom-flue and viaduct blocks, or other refractory materials, pass through the mill on a conveyor belt. After their...