Practical experience with flue gas recirculation in the

preheating zone of a tunnel kiln

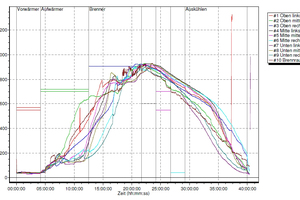

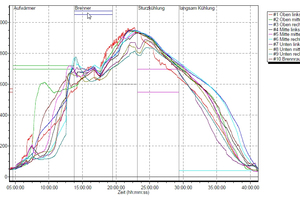

Following the introduction of a process computer-controlled flue gas ducting system for a tunnel kiln at Keller AG’s Paradies Schlatt brickworks a flue gas recirculation system has now also been installed. The aim of both installations was to optimize the quality of the brick products. This practical report describes the challenges and results of the project.

1 Introduction

[1] dealt with the introduction of a process-computer-controlled flue gas guidance system for optimizing the kiln-run quality of heavy clay products at the Paradies brickworks in Schlatt, operated by Keller AG.

The body compositions processed at the plant include one with a very high carbonate content of up to 49 % and correspondingly problematic firing behaviour and which contains papermaking sludge and sawdust. That blend is used to make insulation-grade Imprex/Unipor bricks. Unporosified bricks of higher apparent density are also produced there for purposes of superior sound...