Optimizing kiln run quality with tailored flue gas flow

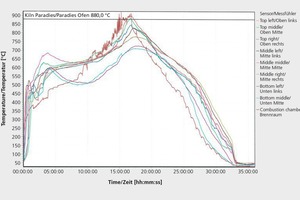

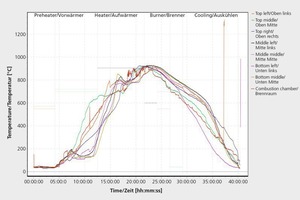

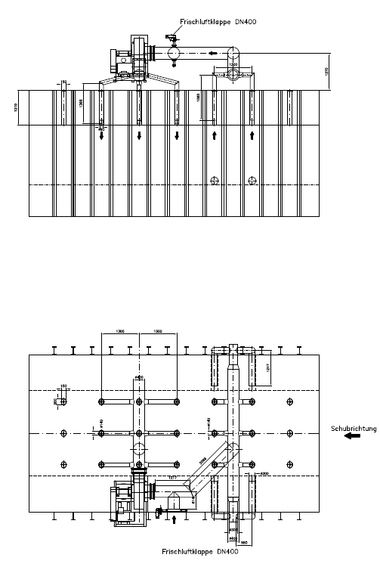

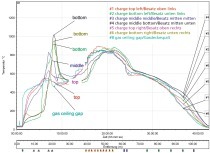

This contribution describes basic firing curve criteria for the firing of heavy and porous products and an optimization project at the Paradies brickworks operated by Keller AG Ziegeleien in Schlatt, Switzerland. The object was to produce bricks without opening materials and insulating bricks displaying low apparent density.

1 Introduction

In brick production, the firing curve is determined in part by the type of raw material employed. This has been the subject of numerous investigations, the facts of which are surely known to any experienced brickmaker. Even for designing the kiln, the kiln contractor needs a raw material analysis for reference. The composition of raw materials dictates how carefully the kiln must be heated, how high the firing temperature must go, how long the holding time should be, and how sensitively the product reacts to cooling. Organic constituents of the type found in natural deposits or...