Trend Industrial Ceramics presents new refractory product

“We have developed a material designated TUZ especially for use in viaduct blocks, deck blocks and other kiln furniture used in the heavy clay industry”, explained Trend’s technical director, Xia Xiayun. “The main raw material in TUZ is reclaimed cordierite-mullite, combined to offer two principal advantages: the thermal shock stability of cordierite and the high-temperature strength of mullite.”

A grain size of 2 mm to 0.1 mm has been used to give an optimum packed density. It allows the finished product to reach a density of 2.0 g/cm3, MOR (modulus of rupture) to 13 MPa and thermal expansion coefficient of 2.4 x 10-6 K-1.

TUZ has been successfully trialled by leading Australian brick manufacturers, with the expert support of the company’s agent there, Annexus (WA), as Wayne Horne, managing director at Annexus, has confirmed.

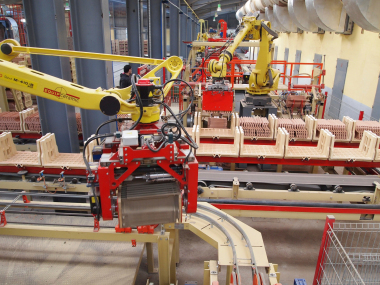

Trend has developed both extrusion and pressing manufacturing methods for these brick kiln products. Having two manufacturing methods gives Trend more options to better satisfy customers’ requirements and offer a full service to the heavy clay industry worldwide. With the extrusion method, shapes with a higher percentage of perforations can be manufactured, lowering the overall weight of the piece. This also increases the thermal efficiency at the end user’s kiln, without any loss in product strength.

Trend Industrial Ceramics Co Ltd

http://en.beijingtrend.com.cn