Automated wall construction - Hadrian X construction robot erects walls using

Wienerberger hollow bricks

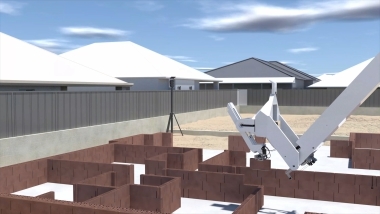

In Wellard, Western Australia, Fastbrick Robotics Limited (FBR), an Australian robotics company, has used a robot to construct a building using Wienerberger Porotherm bricks.

According to FBR, two types of Porotherm bricks were used for the building: double-skin R25 blocks for the exterior walls and single-skin blocks for the interior walls. It was the first time Wienerberger hollow bricks had been used by a construction robot for a commercial building.

The project in Wellard was preceded by an outdoor pilot test in November 2021. The aim was to prove that the construction robot is capable of serving the European market for flat brick buildings. FBR estimates the construction potential there at 700,000 new homes per year. The Australian pilot project will see more single-family and multi-family homes built with Wienerberger bricks.

FBR and Wienerberger AG had signed a multi-phase global partnership agreement in September 2018 for the development of customised brick solutions for Hadrian X, as well as market assessment and business modelling. Negotiations are ongoing between FBR and Wienerberger for the next commercial phase of the partnership.

The robot and its Roman namesake

The construction robot is named after the Roman emperor Hadrian, who lived from 76 to 138 CE. Under his rule, the Roman Empire consolidated its external borders, among other things by building fortifications. The most famous is the so-called Hadrian‘s Wall, near the present-day border between Scotland and England in Great Britain.

The robot should not only significantly increase the speed at which bricks are processed, but also the precision of the processing. Bricks are set with millimetre precision. A dynamic stabilisation system detects influences from wind and vibrations in real time and balances them out. FBR‘s goal is to produce housing faster, more cost-effectively and efficiently in the future, as well as to a high standard of quality. In addition, Hadrian X should enable the mass production of housing even under labour and skills shortages.

The automated and digital solution is designed for the segments of single-family houses and apartment buildings up to two storeys. Depending on the level of difficulty, the fully automated Hadrian X manages to complete a house within one to three days.

The company Fastbrick Robotics (FBR)

FBR designs, develops and builds dynamically stabilised robots to meet global requirements. These robots are equipped with the company‘s proprietary Dynamic Stabilization Technology (DST) and are designed to work outdoors. FBR is the inventor of Hadrian X, the world‘s first fully automated end-to-end masonry robot. In 2016, Fastbrick Robotics was awarded the Western Australian Innovator of the Year Award. FBR markets products for the construction sector along with DST-enabled solutions for other industries.