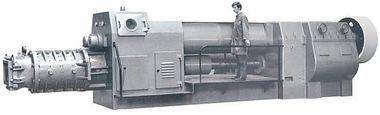

Coated Pressure Head and Extrusion Die: Guaranteed Energy Savings and Optimisation of the Extruded Product

The study and use of a suitable extrusion die makes it possible to reduce clay consumption by optimising the size and weight of the batts, as well as reducing drawing tensions, which have repercussions during drying.

It must be considered that in order to form a batt free of internal tensions, it is necessary not only to pay proper attention to the die, but also to use a suitable pressure head (clay accumulator), which directly precedes it.

The inlet of the pressure head, HE-coated with special self-lubricating polyamide, guarantees better homogenisation of the clay thrust than the traditional steel inlet.

It is well known that clay sliding on steel surfaces is affected by friction (heat generation = energy loss).

Since the friction coefficient of the polyamide coating, which covers the interior of the coated inlet, is significantly lower than steel, the temperature generated is significanty reduced as a result (lower temperature = less energy loss).

Therefore, the use of the coated inlet guarantees, under the same drawing conditions and together with a suitable extrusion die, a decrease in extrusion pressure, corresponding to a lower energy consumption, as well as a homogeneous thrust of the clay at any point of the pressure head.