Every degree counts! - Energy saving in the tunnel kiln

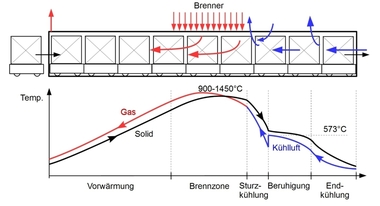

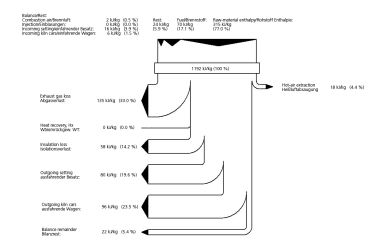

Like almost all branches of industry, the ceramics industry is also affected to a large extent by energy price increases. Especially in kilns with long travel times, energy consumption plays a not inconsiderable role. High kiln temperatures are needed to fire ceramic products. The bricks, clinkers or similar products should reach the required temperatures at all points in the kiln at all times. To achieve this, the kiln is often set a little too high rather than too low „just to be on the safe side“. This increases energy consumption even more and results in immense costs and burdens for the manufacturing companies.

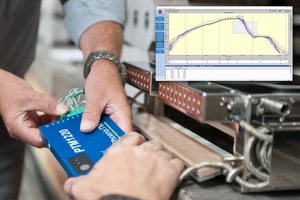

But how can the energy consumption be reduced without generating losses in quality? This requires very precise knowledge of the entire production process. In particular, the oven temperatures should be looked at very closely. Every industrial oven has permanently installed thermocouples that report the oven chamber temperatures back to the control system. However, these only allow very imprecise conclusions to be drawn about the actual product temperatures. In order to be able to assess the exact temperatures at the product in the complete set, PhoenixTM has been offering the proven TS05 measuring systems especially for the ceramic industry for 13 years now. A data logger records the product temperatures at up to 20 measuring points via NiCrNi thermocouples (various types available). For this purpose, the thermocouples are attached to the relevant points in the set. With the removable connection boxes, which can be mounted at any position, the cabling effort is reduced and shorter sensor cables can be used. The water-cooled TS05 heat protection container is mounted under the floor of a tunnel kiln car and protects the data logger here from excessive temperatures, but also against mechanical damage, dust and moisture. At undercar temperatures of up to 500°C, they allow a travel time of up to several days. The kiln car only needs to be equipped with a holder for the container and feed-throughs for the measuring probes.

The optional radio telemetry sends the temperature data in real time to the user‘s PC. In this way, a detailed evaluation of the oven run can be made directly. The evaluation software allows not only the graphical analysis of the firing curve, but also further evaluations, such as the time above a certain temperature, or average or peak gradients. The knowledge gained in this way can be used for kiln control and thus contribute to optimising both product quality and energy consumption.

PhoenixTM GmbH

Carola Konitzer

Dehmer Str. 48

32549 Bad Oeynhausen

Tel: +49 5733 300 28 18

Mail: