High-Temperature Coatings offer energy savings

Operators of all kind of kilns and furnaces are facing significant challenges due to constantly increasing fuel costs and by government pressure to reduce greenhouse gas emissions. This is particularly true in the brick and ceramics industries where fuel is one of the largest cost components of operations. High temperature processing efficiencies can be gained by employing the latest burner or controller technologies or by using insulation to its fullest advantage. Emisshield high emissivity coatings present an opportunity to gain additional savings.

What is Emisshield?

Emisshield is a family of high emissivity ceramic coatings manufactured by Emisshield, Inc. based on patented technology licensed from NASA. This latest NASA emissivity technology was developed for the next generation of space vehicles intended to replace the existing shuttle fleet when it was retired in 2010.

Emisshield Inc. combined their own patented binder systems with the NASA technology to produce high emissivity coatings that will strongly adhere to dense refractories, insulating fire brick, refractory ceramic fiber and most metals. Coating refractories and ceramic fiber in tunnel kilns, batch kilns, roller kilns etc. with Emisshield will provide more even heating, increased productivity, longer refractory life and fuel savings.

How does Emisshield work?

When Emisshield is used, it is applied to the hot face of the kiln. Radiant and convective energy from the burners and hot kiln gases are absorbed at the surface of the coating and re-radiated to the cooler kiln load. A key factor of this ability is the emissivity of the wall surface of the kiln or furnace.

Emissivity specifies how well a body absorbs and re-radiates energy when compared with a blackbody at a given temperature and wavelength. The Emissive Power (W/m2) of a body depends on the physical property of the body or it’s Emissivity. Emissivity is a two-step process in simplest terms involving the absorption and re-radiation of energy at longer wavelengths in the near Infrared wavelength bandwidth. It is totally incorrect to assume a refractory / ceramic wall is a grey body and that it is absorption and re-radiation is a constant percentage of a blackbody at all temperatures and wavelengths. For example, an alumina-silicate refractory utilized in a kiln may have a total Emissivity of 0.8 at 500 °F (260 °C) but at 2000 °F (1090 °C) its Emissivity is only 0.4.

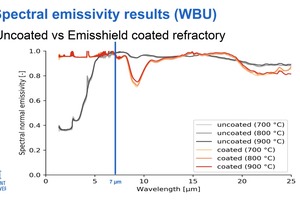

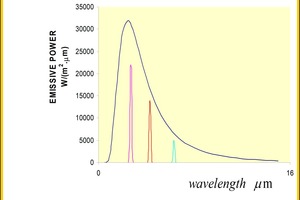

»1 indicates Emissivity (Spectral Emittance measurements) as prepared for Insulating Firebrick by WBU (Western Bohemia University) at different temperatures versus Infrared wavelengths in microns. The key peak infrared wavelengths for emission of radiant energy in a kiln are in the 2-7 micron range, where about 90 % of radiant energy is generated below 6.4 micron in the near Infrared. These are the important wavelength bandwidths and also happen to be the worst Emissivity wavelengths for refractory!

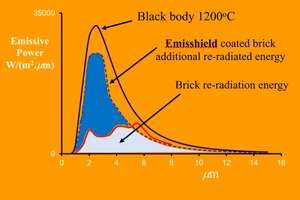

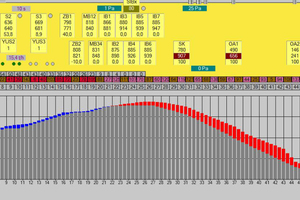

»2 indicates the blackbody, Emisshield and non-coated refractory curves versus wavelength. Several points are in order:

The area under each curve is the amount of energy or Emissive Power (W/m2) re-radiated from the body’s surface (brick, Emisshield or blackbody) to a kiln load (kiln car).

Emisshield is a grey body as evidenced by its curve. Refractory is a non-grey body.

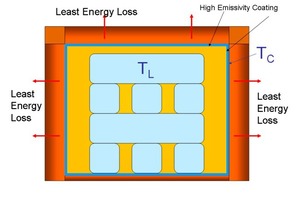

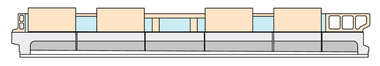

»3 shows a cross-section of a tunnel kiln with Emisshield high emissivity coating applied to the refractory hot face. The thermal energy absorbed by the coating, TC, is re-radiated and absorbed by the colder load, TL. The refractory lining is subsequently cooler and retains less heat energy.

It is important to remember that for Emisshield to be effective, the temperature of the coating surface must be greater than the temperature of the kiln load. The amount of heat re-radiated from Emisshield is predicted by the following equation:

Q = Ew* σ*(TC4-TL4)

Where: Q = re-radiated energy absorbed by the kiln load

Ew = emissivity of the coating

σ = Stefan-Boltzmann constant

TC = wall temperature

TL = load temperature

Since the temperature of the coating and the temperature of the kiln load are raised to the fourth power, it is apparent that Emisshield absorbs and re-radiates the most energy when the temperature difference between the coating and the load is the greatest. In addition uncoated refractories have emissivities, Ew, in the range of 0.3-0.5 at tunnel kiln operating temperatures. The application of Emisshield to the refractory increases the emissivity of the refractory to about 0.9. This means that 90% of the energy absorbed by the coating is re-radiated to the cooler kiln load.

When TC approaches TL the transfer of heat diminishes significantly thus, it follows that in a continuous kiln one would apply Emisshield only to the preheat zone above 1100 °F (600 °C) and in the soak zone. In a batch kiln one would coat the entire kiln walls since Emisshield would increase the rate of heat up and cool down in this kiln type thus, resulting production increases with energy savings. Note, in a continuous kiln heat up time will decrease and cool down time will also decrease as in a batch kiln.

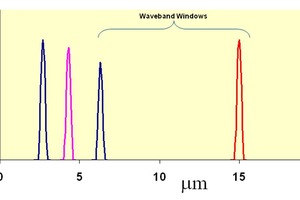

It is also important to understand that the fuel and firing medium respond differently to Emisshield application. Emisshield cannot tell the difference between the two, but the thermodynamic and performance results are different with each fuel source. In a gas fired kiln the increase in radiation from the refractory is not only felt by the load (kiln car) but it also has great influence on and with the hot combustion gases within the kiln. These hot combustion gases have a very low total Emissivity of approximately of 0.2 and are non “grey”. Research work accomplished at British Gas and several European universities found that natural gas actually radiates in very narrow near Infrared bandwidths as identified in Figure 4 (2.7, 4.3, 6.3 and 15 microns). Since Emissivity is a two-steps process of absorbing and re-radiation, the hot combustion gas has the same affinity to absorb and re-radiate at exactly the same bandwidths. Hence, “waveband windows” exist where combustion gas neither absorbs nor reradiates energy and the wavelengths of energy freely pass.

With any surface or material Emissivity and Reflectivity work hand in hand as follows: Emissivity + Reflectivity = 1

A kiln refractory with a low Emissivity will reflect radiant energy at the same wave-length and frequency as it is received and thus, will be reabsorbed by the combustion gas (Emissivity of 0.2). This results in a higher portion of energy not reaching the load.

If one increases the Emissivity of the wall with Emisshield to 0.9 then a greater amount of radiant energy is absorbed and re-radiated over a broader infrared wavelength bandwidth and more energy passes through the “waveband windows” to the load. Emisshield in a gas fired unit allows expansion of the narrow wavelength bandwidths, re-radiating energy over a much broader and continuous bandwidth with significantly more energy.

»4 indicates conceptually “waveband windows” and the smoothing grey body curve produced over a broader wavelength bandwidth by Emisshield systems in a kiln. Emisshield systems in an electric fired kiln will also work but with slightly less energy savings due to the absence of “waveband windows”.

Expected Results When Using Emisshield

Upon preliminary tests done at the Institut für Ziegelforschung Essen e.V. (Institute of brick and tile research center) in Essen, Germany, showing about 6 % energy savings in a small batch kiln, an industrial project has been launched at Ziegelwerk Bellenberg, Germany. On 20. February, 2021 about 400 m² of side walls and ceiling in the preheat zone and burner zone of the tunnel kiln were coated by company CRESS B.V., the European application partner of Emisshield, Inc., with Emisshield refractory coating.

After the restart of the kiln the operator immediately recognized energy excess leading to higher temperatures reaching into the cooling zones.

Step by step burner on times were reduced or completely shut off and the burner control had to be adjusted to get the system back into balance. Starting with 1st of May 2021 the specific energy consumption was monitored carefully and compared to the situation before coating. Due to a sophisticated energy management system according to ISO 50001 the following specific energy data were extracted from the system:

Gas consumption was monitored in the furnace-dryer assembly and compared with the data from 2019 and 2020. Main changes in raw material mixture, amount and type or porosing material and products were taken into account in the calculation as well as major production issues. After about 6 months of monitoring, it can be confirmed that the greatest savings are achieved in the area of the hot air burner in the dryer and in the furnace itself. This leads to an average reduction in natural gas consumption of about 7.5%.

Because of always changing raw material mixture, different amount of porosing material and products, the energy consumption will be monitored further over a longer period to confirm the trend about the energy savings. However, until today it can already be determined that the switch-on time of the burners is shorter than before. Likewise, it could be determined that energy is „pushed“ further into the cooling zone, so that higher temperatures are available at the upper exhaust for the drying process and the burners work less frequently in energy network with the dryer, so that energy savings can also be recorded there. During the next inspection of the kiln (after about one year of operation with coating), the durability of the coating on the brick lining will also be inspected.

At the Institut für Ziegelforschung Essen e.V. (Institute for Brick and Tile Research), the coating was applied to a fiber lining. Here, after more than a year of kiln operation with a wide variety of atmospheres from the firing of a wide variety of products, no change or damage has been observed.

For any further question about the Emisshield coating project at Ziegelwerk Bellenberg, please raise your questions to Tobias Bem (), phone: +49 (0)7306-965040.