Less energy consumption thanks to intelligent refractory technology

Refratechnik Ceramics systems stand for a high level of energy efficiency. If less material requires heating, less energy is consumed. Therefore, Refratechnik produces refractory tunnel kiln car systems in thin-walled formats made of lightweight materials that can significantly cut energy consumption. Highly efficient Refratherm Eco insulation was another step in the right direction.

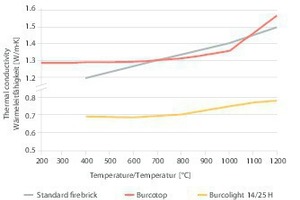

Burcolight

Burcolight meets the important demand of the ceramics industry by reducing the energy consumption in the kiln car area significantly thanks to lower weight of the refractory material. Excellent thermal shock resistance and low thermal expansion make this refractory system a dependable factor in production:

up to 30 % energy savings in the kiln car area

bulk density of only 1.3 to 1.5 kg/dm3

low thermal conductivity and thermal expansion at 1 100° C

also suitable for short passage times

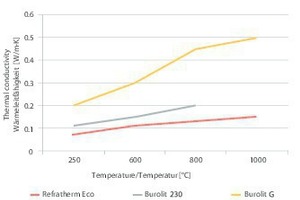

Refratherm

With the aim of higher energy savings, the insulating granulate Refratherm Eco has been developed. Refratherm Eco on the basis of microporous silica exhibits a unique combination of outstanding properties. The material features extremely good insulating properties, and the resulting reduction of thermal conductivity is a decisive contribution to cost savings in the kiln car area. It permits very low structural heights, thereby extending the useful firing space for the brickmaker. Moreover, the excellent workability of Refratherm Eco enables installation time to be cut drastically.

A sintering temperature of 1 550° C and a melting point of 1 650° C ensure reliable operation with firing processes in the brickmaking industry:

up to 20 % energy savings

sintering temperature: 1 550° C

melting point: 1 650° C

high micro-porosity for excellent insulation

low density

extreme low thermal conductivity

The brick industry is already using these energy-saving systems successfully. Energy costs have been significantly reduced. The Refratechnik Group provides resource-friendly and energy-saving products. As one of the leading refractory producers, Refratechnik Ceramics has developed the world’s first series of refractory products that result in a noticeable reduction of energy consumption and the output of CO2 for all industrial sectors: the ES-Series.

Refratechnik Ceramics GmbH

www.refra.com