Three for one common goal – The story behind Gevelklaar system Prefabricated concrete elements finished with insulation and brick slip facade

Near Harlingen on the North Sea coast in the Dutch province of Friesland, precast concrete element factory of the company Spaansen is located. For the past three years, ready-to-build, prefabricated elements of the Gevelklaar brand have been produced there. These are precast concrete elements with window and door reveals, integrated cable ducts, an insulation layer of expanded polystyrene (EPS) and clinker brick slips on the facade side. That allows concrete precast elements to acquire a traditional brick slip facade.

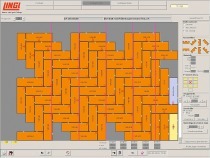

Production is fully automated. The brick slips are laid by robots following a pattern previously defined in a CAD-programme according to the client‘s wishes, with the help of the RoboBrick system from Vandersanden and special hardware and software developed by the company Lingl from Krumbach. ZI went to Harlingen to see the plant and to talk to the project partners about the hurdles on the way to market maturity and whether the Gevelklaar system is the future of housing construction. Our talking partners were Thom Spaansen, Manager of the Gevelklaar factory, and his colleague, Raimond Lotz, Director Operations of Spaansen Bouwsystemen, Karl Liedel, Head of Sales at Lingl, and Victor Albers, Business Manager Industrial Clients at Vandersanden.

How did the whole operation start? Who had the idea to put it all together?

Karl Liedel (KL): Spaansen initially developed the idea. They first got in touch with Vandersanden about it and then with Lingl. Vandersanden was responsible for the quality reasons. Lingl developed the machine. Vandersanden and Lingl already had a long-standing and successful relationship. Vandersanden told Spaansen that they could provide the system with all the necessary ingredients, i. e. the brick slips and the glue. However, due to their concern over the quality of the product they advised against a manual production process and advocated an automatic solution. To provide this, Vandersanden recommended us.

Victor Albers (VA): Coincidentally, Spaansen and Vandersanden were looking at the same idea at the same time from different angles. Spaansen was investigating ways to enhance their original product, concrete prefabricated walls, with insulation and brick slips. Vandersanden was actively looking into ways to provide their customers not only with brick slips but with a comprehensive wall system.

When did you start implementing this idea?

Thom Spaansen (TS): We first started developing the idea in earnest about four years ago. It took us about a year to establish the new factory. When that was ready, Lingl brought in their machine from Krumbach. The whole process proceeded very quickly.

KL: We had already built machines for wall prefabrication in the last 15 to 20 years. With Spaansen it was the first time we focused on brick slips. In this endeavor, our prior experiences were very helpful.

Prior to delivery we ran a lot of tests in our workshop in Krumbach together with Spaansen. The setting machine represented a fundamentally new development in the industry. We wanted to make sure that the machine would start working as intended as quick as possible after installing it at Spaansen‘s production site. The whole process extended our understanding and capabilities concerning building and prefabricating walls and especially in programming. It was quite a challenge for Lingl. We are quite happy having finished it successfully and will use this experience and expertise in the future to provide solutions for prefabricated walls independent of material, wood, brick, concrete etc. We believe that prefabricated walls will be the future in construction.

How long did the installation process in the factory take?

KL: Development and construction took place in Krumbach, the assembly here in Harlingen was finished in two weeks.

TS: Testing took considerably longer. There were pretests in Krumbach for six weeks, and another round of testing after the assembly in Harlingen for three months. The people from Lingl were here for the whole test duration, first the technicians, later the software engineers. After that, we managed on our own. However, they visit us every year.

We had to school our personnel, too. Fortunately, I had been in Krumbach myself to learn how to operate the equipment. The machinery is quite challenging. Basic operational knowledge requires about three months training for a new employee.

It helps that Lingl‘s people were here for months. We got to know each other and developed strong ties. That helps us fixing problems really fast.

KL: Lingl is able to provide permanent service from Krumbach in each phase of production. That is an offer to all our clients, 24/7 and worldwide. A key element to this is good personal relationships.

What were the greatest challenges?

KL: One challenge was the complex task profile of the machine. It was a question of window reveals, angled slips, normal slips, different bracings, slips differing in colour, length and thickness. The machine also had to be able to do all this in a certain cycle time. The open time of the adhesive had also to be taken into account.

Raimond Lotz (RL): The design had to be very compact to be able to produce everything in one line.

KL: Exactly. The final design we could only determine at the end, because in the course of the project, it grew and the machine became more complex. At first it was just about the surface, then about the window reveals, then we had to figure out the bottom at the base, take UV light into account, insulation, evening and levelling everything to within a millimeter, which software company to involve. It was a major project involving many clever people from all three companies.

Another major challenge lay in the slips themselves. Despite all the automation and rationalisation, these are natural products with small variations. The dimensions vary slightly from brick slip to brick slip. To avoid different joint widths and distances, the machine had to learn to place the slips centrally.

RL: Developing the software was the biggest challenge for Lingl. To automatically get the right brick in the right place in the right time was a tremendous achievement.

KL: Yes, getting to the point where we could feed all the information connected to an individual brick slip to the robot so it could pick up the right brick and put it into the right place, that was an exceptionally challenging piece of programming. F. ex., if a slip was broken, the challenge was to avoid the program to get confused by this.

That was solved by us at Lingl together with Spaansen. I want to stress this point: Finishing a project that complex is only possible with a partner you can trust and work closely together.

Where there any regulative hurdles or problems?

VA: Achieving acceptance in the market was the biggest challenge. The glue was the point of contention. Before we started, there already were similar, but inferior products on the market. Glued by hand using an inferior glue, the bricks kept falling from the wall. That gave the whole market a bad reputation, especially since there was no required standard and no product regulation. We had to prove our product was as good as promised every time. Now, finally, there is a rule stipulating exactly what to test, so we can show that our product adheres to the regulation.

KL: Confidence in the prefab market must first be built up. There are also doubts among manufacturers of facade bricks. Hence the many tests and certifications.

In Gevelklaar, every brick slip that is glued on is documented with a log file that is kept for ten years. In this way, all information about the production circumstances, time, temperature, adhesive, can be kept for each brick slips. The slips are also numbered and identifiable. This ensures confidence and a functional guarantee. With a certificate, you can survive on the market and prove quality.

Is there a demand for prefabricated concrete elements with brick slips installed on them?

RL: There is a demand. When we first started in 2003 with one factory producing precast concrete elements, this was a new system in the Netherlands. We were among the first producers. Before that, limestone was the most popular construction material. We were able to compete successfully with limestone and establish ourselves on the construction market.

There came a moment when we realised that what the Dutch market was really asking for was a comprehensive solution with finished elements. Finishedness mattered more even than the material. We contacted our four biggest contractors and asked them what they prefer. Apparently, the Dutch people are very traditionally minded. Most want a house with red bricks, maybe with some black mixed into. That’s when we started to look for a way to improve our concrete precast elements with these features. That’s how we came up with the Gevelklaar system.

The demand proves our success. We already built the walls for 1,800 houses in the last three years, not yet running on full speed. The whole year 2024 is booked out. We are already selling for 2025. All our new clients are only interested in the Gevelklaar products.

We are selling the elements across the Netherlands. We also register an expanding demand in element types. They also want stairs, the inner walls, and prefabricated bathrooms.

VA: The project, as the demand for it, is driven by several points. First, there is a shortage of workers for construction sites that will not abate in the future but will get more urgent.

The second point are quality standards. With prefabricated walls you ensure a constant and consistently high degree of product quality which is monitored throughout the whole manufacturing process. That is not possible in the same degree at the site. As standards of legislation get more and more severe, controlled manufacture and installation, like it is done here, are gaining much more importance.

Other factors include using and wasting less material, requiring less space at construction sites, making it better suited for narrow surroundings like in inner cities. The main advantage, however, is that you require a lot less movements. Normally 144 transport movements to the site are necessary, with prefabricated elements only about 20.

What are the advantages of the automatic setting?

TS: The whole production process is running highly effective and automatic. We are working in three shifts with five persons. At this time the output is approx. 100,000 bricks a week, compared to a brick layer setting about 800 bricks per day. And the quality is much higher.

On full speed, which we reached in February 2023, this factory can produce the walls for 1,200 houses every year.

VA: Also, getting the machine to set different patterns is no problem at all. A human brick layer has a harder time adjusting and takes more time. The more complex the pattern, the cheaper Gevelklaar gets in comparison with manual labour. At the moment, the system is competitive with traditional Dutch house construction.

KL: Looking further, Prefab-construction and especially Gevelklaar can save a lot of time during construction. Due to the automated production process in the factory and just-in-time delivery. That means less expenditure and more revenue for the building owner, as he is able to sell or rent the house as well as pay back credits earlier.

RL: With Gevelklaar walls, a single construction crew can build four to five row houses in one week.

VA: Accordingly, the interest in the system stems both from concrete factories and building companies. The prefabricated elements can be used for single family homes, duplexes, and apartment houses up to five storeys, according to government regulations. Using these elements, construction companies save resources and manpower, allowing them to flexibly engage even in regions outside their home areas.

The demand for affordable housing in the Netherlands is huge. Government plans for the third decade are 100,000 flats per year and a million in total. In the first three years, building efforts already are behind by 90,000 flats. We need more companies like Spaansen.

KL: What we have achieved here, I believe, is only the initial step. As Raimond implied, the automated production of prefabricated elements will encompass more and more complex products, whole units like, f. ex. bathrooms, in guaranteed quality and BIM-compatible. This last point is very important, as Building Information Modelling gets more and more relevant in the construction business.

The building system represented by Gevelklaar here in Spaansen will be the future because it is the only way to fulfil government obligations around housing development. Lingl will be ready to assist its partners in implementing the necessary production capacities.

A last question to Lingl: Are you planning to equip other prefabricated concrete elements producers with „Gevelklaar“ machines?

KL: Of course, we believe that there will be a worldwide demand. Thank you, Thom and Raimond, very much, for being open-minded and allowing us to guide potential competitors and the press through the factory to showcase it. The more companies are convinced of the system, the more the market will use and accept the system. There are many reservations yet. Showing the system and demonstrating its numerous advantages will help to eliminate them.

TS: Thank you, Karl. We are very happy with the system and we believe you are right. The Gevelklaar system together with BIM allows for extremely streamlined production and construction processes. We can deliver just in time four to six elements per transport for a total of 40 elements per day to be used at the construction site. Working with our 3D-modell, the project manager knows the order of elements, production and delivery are attuned precisely to that. It’s a very efficient process for everybody involved. We are experiencing an exponential increase in demand. Quite possibly at a future date, we have to expand our production capacity.

Gentlemen, thank you all very much for this interesting discussion.

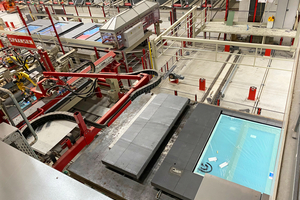

Afterwards, there was a guided tour through the production. The Gevelklaar production line comprises six different stations:

Station 1: Placement / removal of the finished walls

Here, one or more walls are positioned on the transport pallet. The operator receives the coordinates for placing the walls via a visualisation. In this step, the data for the production process are requested from the master computer in order to then supply the machine with the correct data.

Station 2: Cutting EPS flat

At this station, the EPS is cut flat with a maximum deviation of +/-1mm. This is achieved by a proven hot wire cutting system.

Station 3: Cleaning

This is the cleaning station where residues from the EPS are extracted, thus providing a clean wall element for the following station.

Station 4: Adhesive application

Here, the 2-component adhesive is applied by a robot. The two components are fed to the robot via a pipe system. The two components are not mixed until the adhesive is applied at the tip. The type and shape of the adhesive application is specified by the CAD programme. Each wall has its own data, which are transmitted to the robot. The adhesive has an open time, i.e. the time between application and bonding, which varies between 30 - 45 min.

Station 5: Laying station

This is the heart and the most complex part of the machine installation.

Station 6: Quality control / drying station

Each wall is visually inspected once again for quality defects. The wall is also given time to dry before it is finally removed and stored at Station 1.

Machine data

Output: 2;000 pieces/hour

Maximum length of slips: 300 mm

Maximum thickness of the slips: 30 mm

3 different types of slips can be processed in one wall at the same time. This means 3 different thicknesses and/or 3 different colours

Maximum dimension of the wall element:

4,000 mm x 12,500 mm

Minimum dimension of the wall element:

2,500 mm x 600 mm