New plant for prefabricated brick elements

Redblocsystems has started up a new production plant for prefabricated brick elements in St. Georgen, Austria. In the production line developed in collaboration with Sabo, the Greek plant engineering company, walls measuring 11.5 cm to 50 cm in thickness, up to 6 m in length and up to 3.5 m in height can be fabricated. The owners of the new plant include the German brick manufacturer Hörl und Hartmann.

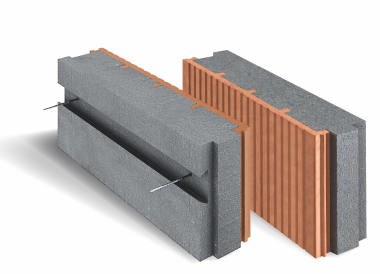

Both unfilled clay blocks and those filled with insulating materials are suitable for prefabrication of the wall elements. Up to six different block sizes can be used, for example, whole bricks, window-rebate bricks or height-levelling bricks. In the finishing centre, another new development, cuts for roofs, cut-outs, stair bearings, sockets or milled grooves for supply lines are performed fully automatically.

Growing interest in

automated production

“At the moment, we’re getting lots of enquiries concerning our technology, especially from European countries, but from Russia and overseas, too. Obviously, the time is right for it,“ said Markus Pichler, the obviously pleased founder and managing partner of Redblocsystems GmbH in Wels, Upper Austria. There, Redblocsystems has been producing prefabricated wall elements from solid building materials since back in 2007.

Pichler explained how growing interest in this type of equipment was being shown primarily by brick manufacturers and building contractors, but added that the company was getting more and more enquiries from investors outside the industry, too. In a somewhat different constellation, he went on to say, Redblocsystems would soon be setting up other plants in Vorarlberg/Austria and in Buchenbeuren near Frankfurt am Main/Germany. A plant for the fabrication of walls from aerated concrete was currently going into operation in Southern Italy, added Pichler. In respect of building types, almost everything could be produced. “We supply mainly prefabricated elements for detached house projects, terraced houses, multi-storey housing, retirement homes, buildings for assisted living, but also for commercial buildings,“ explained Pichler.

Developed together with Sabo

The entire plant was developed together with Sabo; the Greek plant engineering company was responsible for the electronics and programming of the plant up to the interface to the CAD software. Markus Pichler: “In the selection of the components used, we gave Sabo clear specifications, which were met perfectly.” So, only products from renowned international companies, such as SEW, Fanuc, Siemens or Festo, were used. “For the CAD software, we work with Nemetschek-Planbar,” added Pichler.

Digitalization as well as increasing time and price pressure are forcing companies in the building sector to think about time- and resource-saving alternatives to conventional installation processes. Markus Pichler sees one crucial advantage of prefabrication in the consistent quality of the solid walls: “The system always lays the blocks in exactly the same way. Regardless of the temperature, weather conditions, and the employees.“ The advantage of this consistent quality: “There are as good as no complaints on the construction site.”

The prefabricated elements are transported to the construction site, and there put in place easily, quickly and precisely by just a few workers and a crane. A crucial factor for the efficiency and time saving is the patented Redbloc adhesive. This specially developed dry adhesive replaces conventional mortar, bonding the blocks together in a very short time, and eliminating the need for long and weather-dependent drying times. The wall elements can be transported to the construction site and put in place just an hour after they are produced,” explains Pichler.

Turnkey production lines for SMEs

Redblocsystems’ production lines are available in three models: Redbloc Semiauto, the semi-automatic entry-level model for medium-sized building companies, Redbloc Economic, the extension of the Semiauto line to a fully automatic system, and Redbloc Advanced, the high-end system. All production lines are engineered as turnkey systems and individually adapted to meet customer requirements. Companies that want to produce with Redblocsystems production lines become a licence partner and profit from all further developments, employee training, technical support and consulting.

Redbloc Semiauto

The turnkey production line Redbloc Semiauto is tailored to the requirements of medium-sized building companies and fabricates wall elements semi-automatically. This enables easy entry into automated solid wall fabrication. Set-up of Redbloc Semiauto systems is uncomplicated: “We need just three weeks for assembly and commissioning at the production facility,” promised Markus Pichler. If required, the systems could be retrofitted to a fully automatic Redbloc Economic production line for larger fabrication capacities, said the managing director. This entails installation of an automated feed system, a water-jet cutter and linking to CAD programmes.

Redbloc Economic

On top of the advantages of the Redbloc Semiauto line, this cost-effective solution offers automation or production preparation and wall cutting. Here Nemetschek Precast CAD software is used for easy calculation and modularization of the wall elements. Whole and half clay blocks with adapted perforation pattern can be used. The production line is fed automatically with blocks. A water-jet cutter ensures the automatic cutting of the wall elements in every form. The production capacity with Redbloc Economic runs to 350 m2 wall elements per work shift.

Redbloc Advanced

The high-end Redbloc Advanced system for processing filled building materials offers more advantages alongside those of Redbloc Economic systems. It only needs whole blocks as the system itself fabricates any half-sizes, adapter pieces, and boreholes for the lift-off rods from the whole blocks in a fully automatic process. Moreover, walls without open cut surfaces at the wall ends or for window soffits can be produced. At the sawing station, wall elements can be cut into any shape by means of a diamond wire saw or water-jet system. The water jet system can be used to precision-cut installation ducts, plug sockets, electrical lines or water pipes.

Trockenklebeverfahren

Redbloc-Massivwände werden mittels Trockenklebeverfahren hergestellt. Der patentierte Redbloc-Trockenkleber ersetzt herkömmlichen Mörtel und bindet in kürzester Zeit ab. Lange und witterungsabhängige Austrocknungszeiten entfallen. Das Wandelement ist bereits eine Stunde nach der Herstellung transportfähig. Der Zwei-Komponenten-Kleber wurde gemeinsam mit dem Technologiekonzern HB Fuller entwickelt.

Ausgangsmaterial: alle großformatigen massiven Baustoffe wie z.B. Ziegel

Produktionsdauer: von der fertigen Konstruktionszeichnung bis zur fertigen Wand etwa 1 Stunde. Die Wandelemente sind sofort transportbereit.

Produktionsleistung: ca. 150.000 – 200.000 m2 Wandelemente pro Jahr. Die erzielbaren Leistungsdaten hängen von den verwendeten Formaten und den Größen der Wandelemente ab.

Automatisierungsgrad: vollautomatische oder halbautomatische Produktionslinie

Wandstärken von Wandelementen: von 10 bis 51 cm

Maximale Höhe einer Wand: 3.500 mm

Maximale Länge einer Wand: 5.000 – 8.000 mm

Personalbedarf: 5-6 Mitarbeiter

Return of Investment: ca. 3-5 Jahre

Notwendige Hallengröße: ca. 60 x 20 x 6 m für vollautomatische Produktionsanlagen, ca. 30 x 18 x 6 m für halbautomatische Produktionsanlagen.

Zusätzliche Optionen: Schleifanlage zum Erreichen der Planparallelität von Baustoffen und ein Bereich zur Fertigung der notwendigen Halbformate können zusätzlich in die Produktionslinie integriert werden. In der Lieferung sind CAD Precast Software, Anlagendesign, Montage, Schulungen, Inbetriebnahme, notwendige Zeichnungen, sowie vollständige Dokumentation inbegriffen.