Wienerberger presents brick robot WLTR for the first time in Austria

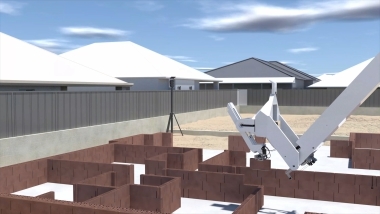

According to their press release, Wienerberger Austria is the first company in Europe to launch a commercialised masonry robot on the market after just three years of development. WLTR was developed in the Czech Republic and builds brick walls over three metres high with an average output of 5-6 m²/hour. It is primarily intended for use in the construction of industrial buildings and apartment blocks.

The concept for the WLTR mobile construction robot was already tested by Wienerberger Czech Republic with the start-up KM Robotics in July and October 2020. High-quality results with high execution quality were achieved. The official go-ahead for the two-and-a-half-year project was given in February 2021. It was led by Wienerberger Czech Republic together with KM Robotics and the Czech Institute of Informatics, Robotics and Cybernetics (CIRRC) at the Technical University in Prague. Robot WLTR was presented in Austria for the first time on 14 November 2024.

Johann Marchner, Country Managing Director of Wienerberger Austria: „The construction industry is facing major challenges in times of digitalisation, the high demand for affordable construction and housing, the prevailing shortage of skilled workers and the goal of making the often physically demanding work on construction sites easier. As an innovation leader in the industry, Wienerberger sees great potential in automation, prefabrication and robotics to realise construction projects faster and more cost-effectively - while using fewer resources and with less labour. And we will be able to achieve this in future with the help of WLTR.“

Functionality and performance of WLTR

WLTR was primarily developed for the construction of long walls in industrial buildings, schools and other large buildings and automates the brick laying process. It works continuously both indoors and outdoors with minimal human supervision, requires only water and electricity to operate and significantly reduces the physical strain on bricklayers on site.

WLTR is equipped with the latest sensor and LIDAR technology, which ensures precise brick placement and movement while guaranteeing safety and efficiency on construction sites. In order for the robot-assisted masonry project to be fully functional, a special, patented brick had to be developed: the „Robot Ready“ Porotherm brick. This has two special grooves on the sides of the wall that allow the robot to handle it seamlessly. The masonry robot is able to erect brick walls up to 3.25 metres high from the base of the masonry - with an average output of 5-6 m² per hour.

But the brickwork robot can not only erect brick walls, it also revolutionises construction by integrating a sophisticated digital platform. It improves planning and efficiency by integrating itself into the planning and construction phases and utilising precise digital data. The robot generates extensive metadata that ensures high construction quality and comprehensive documentation, which is valuable both during and after the construction phase. It also optimises ordering, logistics and site management, transforming traditional methods into a more digitised, precise and information-rich process.

Use on construction sites

Wienerberger planed to realise the first test construction site in Austria in 2024. After that, WLTR will also be ready for use on domestic construction sites. Seven robots are currently available for hire by construction companies. Further models are to be added in the coming years. The ongoing development of WLTR promises to integrate further advanced functions that will make it suitable for a wider range of applications, including residential buildings.