Industry 4.0: Efficient engineering processes with "OPAK"

Engineering processes are to be carried out more intuitively, faster and more efficiently in future, the individual automation components will have a digital memory: these are the aims pursued by the specialist for automation solutions, Festo AG & Co. KG, together with partners from science and industry in the joint research project "OPAK" (open engineering platform for autonomous mechatronic automation components in a function-oriented architecture).

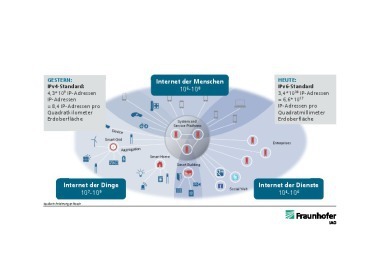

In the "OPAK" research project subsidised by the German Federal Ministry for Economic Affairs and Energy the partners are endeavouring to make the increasing complexity controllable. Dr. Volker Nestle, Head of Future Technologies at Festo, explains: "We are dealing with two topics in this project: on the one hand we are simplifying the engineering process and making it much more efficient; and on the other hand, we are developing components that have a digital memory – the first step along the road to intelligent components for Industry 4.0."

Simple engineering processes

To make the engineering process more intuitive and efficient, a virtual emulation of the production plant is generated in "OPAK". This allows all processes and functions to be simulated and tested by means of the engineering software already at the planning stage – even before the facility is actually built. The developer then only devises the desired automation processes, without having to deal with abstract commands in the programming of control units. The engineering system carries out a plausibility check during the planning phase, so that right from the start only components and configurations can be selected that are technically feasible and appropriate. The developer can therefore concentrate on the actual automation task and its solution. The detailed steps for the technical implementation are carried out in the background.

Components with a digital memory

As a requirement for generating a virtual emulation of a production plant, the components must already incorporate all information needed for operation in their integrated controllers. In combination with adaptable interfaces that reduce the requirements for assembly, configuration and system integration to a minimum, the components are thereby made suitable for "plug and produce" applications: like USB interfaces in computer systems that allow connected systems to autonomously register with the host computer and communicate with it, in the factory of the future even individual components will be able to register with the production plant.

The first outcomes of the "OPAK" project include the prototype of an integrated stopper module. This combines in one single component both the necessary actuators and the sensors and control elements for stopping workpiece carriers on a conveyor belt. The function of the stopper module is made available to further systems via a standardised interface.

A demonstration system for practical research

At the Hannover Messe an exemplary industry cell will be presented. Visitors can see how a flexible system can operate in the factory of the future – from the engineering up to commissioning and regular production. Festo is showing the "OPAK" demonstrator in Hall 15, Stand D07.

Festo AG & Co. KG

www.festo.com