Reichenbach GmbH presents innovation for synchronous belts in materials handling technology

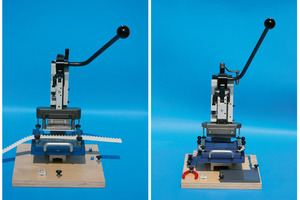

A closed ring without beginning and end – that is how a synchronous belt runs in a machine. If a belt is damaged, the firm can perhaps face a problem: In order to install a new endless belt, a large part of the plant must be dismantled if necessary – provided that the firm has reserve stocks of synchronous belts in the right length for each transport section anyway. Synchronous belts are also available as rolls, but without careful preparation of the belts a stable, durable end connection is not possible. Before hot welding, the ends must therefore be cut in a Z or finger shape so that they interlock. For this process the Reichenbach GmbH in Eichenau near Munich – the company itself is a supplier of synchronous belts and transport belt solutions – has developed the mobile synchronous belt punches Z-8 and Z-14 which allow repair work or the new installation of existing rolled ware quickly and without any problem.

Finger punch and heated press enable stable endless connection

The compact punching devices weighing only around 30 kg are designed for polyurethane synchronous belt qualities and can even cut through steel cords. The model Z-8 is suitable for the belt constructions T 5, T 10, AT 5 and AT 10; the model Z-14 can punch belts up to T 20 and AT 20. Both versions can be used for all standard widths between 20 and 75 mm; a further development for synchronous belts with a belt width of up to 150 mm is already being developed. With a two-knife technique the punch Z-8 cuts one indentation of the Z connection into the synchronous belt in each punching process, before it is pushed on one notch further for the next indentation. On the other hand the punch Z-14 has one knife in combination with a template matching the respective belt profile, whereby the template guides the knife. When all cuts in one direction have been made, the punching knife can simply be slewed through a defined number of degrees to complete the indentations. After punching, any protruding wires of the traction support can be removed simply with a side cutter.

When both belt ends have been punched, the new synchronous belt can be inserted in the synchronous belt heated press. With the portable heated press of the Reichenbach GmbH the ends can be welded in an uncomplicated process to form a loadable Z connection, so that the endless belt is restored. For quick cooling of the heating unit, a handy cooling system is additionally available, consisting of a water container with integrated pump. As a rule, the entire procedure lasts only 30 to 60 minutes; afterwards the machine is ready for use again.

Compact repair set for transport lines with synchronous belts

Through the possibility of taking the new synchronous belt off the roll and cutting it on the spot to the required length in each case, the expenditure for stocking is also reduced in the company, because it is no longer necessary to stock belts to fit each transport section. The first firms – for example an equipper of brick plants – are already relying on these advantages and passing them on to their customers. Especially in brick manufacturing, where the pressed, dried or fired bricks are often transported on ten or more synchronously running belts, already one single defective support belt can cause considerable costs. The punches are supplied complete with spare knives in a handy transport case. The Z-14 punch can be fitted with different synchronous belt templates. The punch, heated press and cooling system are also available as a complete set in a matching equipment case.