Original technology pays off: this is a core message of the VDMA Pro-Original campaign „Choose the Original – Choose Success“. The campaign was initiated to increase awareness of the value of original technology on international markets and to present a common front against product piracy and copyright infringement.

For 140 years, the name of Händle has stood for quality and reliability worldwide and therefore inspires confidence among its customers all over the world and ensures them production reliability. Nobody knows our machines better than we do and this is how we secure our know-how edge over third-party suppliers.

Increasing requirements for products and therefore for production plants do not automatically have to lead to rising (energy) costs. Händle has, for instance, already successfully implemented improved concepts centring on energy efficiency with machine and process optimization based on:

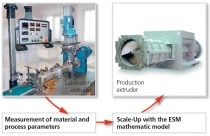

› �Consultations concerning raw material composition based on determination of the necessary parameters and analysis of the raw materials to be processed in its in-house laboratory

› �Design of the machine with our in-house developed design program ESM (Extruder Simulation Model)

› �Geometry optimization with data analysis (including thermophotography) on site at the customer’s facilities (e.g. optimization of the auger pitch, auger length, pressure head geometry of the extruder)

› �Selection of optimal wear parts

› �Optimal design of the drive power

› �Detail optimization based on years of experience e.g. with separate paddle

drives in the extruder for optimization of the

delivery rate and therefore

reduction of the energy re

quirement

› �Process optimization based on optimal machine selection and optimal process flow

› �Online monitoring of the operating data enables intervention in the machine parameters

Besides innovativeness, Händle successfully asserts itself against the massive international competition on the market with worldwide service response and personal customer support on site. In contrast to many other brickworks machine manufacturers, Händle constantly keeps around 5 000 replacement and wear parts in stock. For emergencies, flexible and fast single-part manufacture is available.

“With Händle, our customers choose an independent partner who can work with all other suppliers”, explains Gerhard Fischer, Managing Director at Händle GmbH Maschinen und Anlagenbau. “Customers appreciate the fact that they can count on us to keep to planning, assembly and installation times, which in turn enables them to quickly evaluate the financial success of the resources tied up in the company project.”