From quarry to shaping – prerequisites for optimally planned preparation and shaping plants

In brick production, central importance is attached to preparation and shaping. In a given heavy clay plant, however, dryer and kiln account for some 55% of the overall investment, while preparation and shaping add up to only about 17%. In some cases, therefore, preparation and shaping are not given their due attention. That is thoroughly unjustified, considering that preparation and shaping are what sets the stage for high-quality end products. Mistakes made here cannot be ironed out further down the line. When trouble is encountered in drying or firing, preparation and shaping are usually suspected as the cause. Hence, the main objective of preparation- and shaping-plant optimization specific both to raw material(s) and product(s) is to rule this out from the very start. The following contribution investigates the prerequisites by way of two case examples.

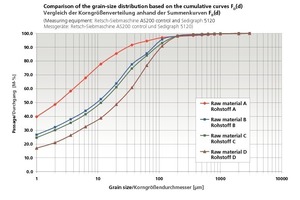

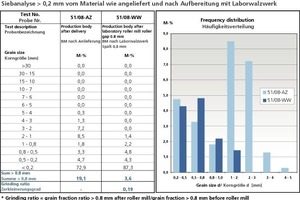

The basic prerequisite is precise knowledge of the raw material‘s working properties and its behaviour during preparation, shaping, drying and firing. Since most of the essential pertinent data come from the laboratory, the following information and comments are to be viewed largely from the standpoint of a ceramic laboratory operated by a major producer of preparation and shaping machines, Händle GmbH Maschinen und Anlagenbau.

1 Planning principles

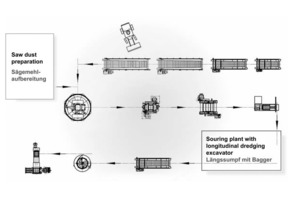

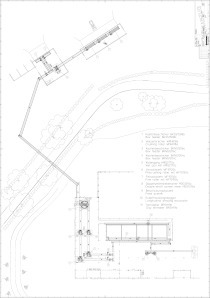

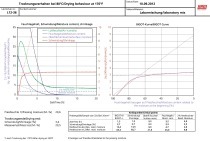

A few of the most important factors for the design of preparation and shaping plants are shown in »1.

1.1 Data acquisition