Gazstroy brickworks now producing with Händle preparation and shaping equipment

Conceived as one of the Russian Federation‘s largest, most modern brickworks, the plant has two production lines. Line A turns out porosity-enhanced backing bricks in sizes ranging from Russian standard format (250 x 120 x 65 mm) to large-format clay blocks (510 x 250 x 219 mm) with brick densities between 1.25 and 0.8 kg/dm3. This is the first time that rectified large-format clay blocks with a granular mineral filling are being manufactured in Russia. Line B is turning out high-fired façade tiles and clay pavers, each in two different sizes (250 x 120 x 65 or 88 mm). The clay pavers have an apparent density of 2.1 kg/dm3.

Whenever necessary, the production program can be re-adapted to changing market requirements.

The employed brick clay is highly plastic, fine-grained and shortened with sand. The working body for the backing bricks is porosity-enhanced, and the working body for the pavers and façade tiles is mixed with fat, refractory amending clay.

Preparation and shaping

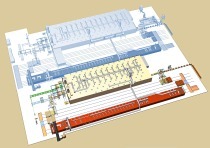

Both the size of the preparation and shaping plant and the implemented technical standards constitute milestones for the Russian heavy clay industry as well as for Händle as the plant‘s implementing contractor.

The wholly new facility was installed on the premises of an old Russian brick manufactory in Ryabovo, 60 km south of St. Petersburg, and commissioned in record time – June 2011 – with ultimate handover of the Händle-built preparation and shaping plants to the customer taking place a mere 18 months after the contract was signed. This gave the Händle company yet another chance to demonstrate its prowess as a leading equipment contractor for preparation and shaping applications.

An upcoming issue of Zi Ziegelindustrie International will feature a detailed description of this major – and exceptional – Russian brick factory.