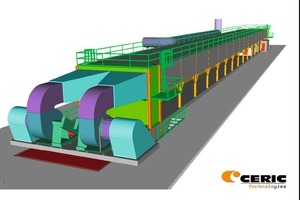

Accelerated drying, easy

maintenance, a wide variety of dried products and low energy consumption – these advantages of Ceric’s rapid dryer for perforated bricks have convinced a new client: Ladrillos Lark in Peru. In 2008 the company decided to invest in a technologically advanced line for the production and drying of hollow bricks and hourdis blocks. This line was successfully started up at the end of October 2010.

With this new Ceric rapid dryer, Ladrillos Lark reduced the drying time for its products from 30 to 3 hours. Thanks to this considerable time saving, Ladrillos Lark has cut its production times and increased its capacity for saleable products, especially for hollow products and hourdis bricks. With the volume and quality of its products, Ladrillos Lark has established its market leadership in Peru.

This rapid dryer and the dedicated handling systems are not only a technological advance for the client, but also a showcase example for the clay brick and roofing tile industry in expanding Peru.

Close to the clients worldwide – for their development

The challenge with this new dryer was the need to reconcile the production conditions (varied products, specific mixtures) and to make the rapid dryer technology that has already been tried and tested in Europe, the Mediterranean countries and the Middle East suitable for the technical requirements specific to Peru, e.g.

› �Bodies with very special properties

› �High mechanical product strength to comply with the seismic standards

Thanks to its fired clay expertise, and with a special mixture, Ceric was able to adapt its process and its technology:

› �The overall dimensions of the dryer and the air ducts ensure efficient ventilation for all types of products and consistent product quality

› �Smart and scalable process control (drying time, temperature, moisture, ventilation)

› �Reduced drying time (from 3 to 5 h), thanks to the unique design of the rapid dryer, with longitudinal and continuous ventilation

Naturally, the rapid dryer is integrated in a Ceric process line, and meets the client’s shaping and production requirements. The main elements to ensure the best possible operation of the line are:

› �Multi-wire cutter for different types of products

› �Automatic loading and unloading of products

› �Automatic setting of products on the cars

With the successful realization of this project, Ceric has again proven its capability to implement international projects and adapt equipment to the needs of its clients in South America.