New projects spur Verdés’ growth

In the first half of the year Verdés signed important supply contracts in the Maghreb region, mainly in Algeria and Morocco. SARL Boukhanoufa Mourad Produits Rouges and SARL Briqueterie Ennadjah Ouel Amel were some of the major projects. The two projects are based on similar concepts, but designed for different production capacities. The preparation areas consist of a grinding and mixing line with primary crushers, desintegrators, hinged roller mills and double-shaftmixers for the humidification and addition of additives to the clay. Both preparation lines end in an intermediate clay storage unit.

Boukhanoufa plant

The first stage of the shaping line has been designed for processing 200 000 t per year. It basically consists of a box feeder, a hinged roller mill for refining the clay with rollers measuring 1 200 mm in diameter that operates with a roller gap of 0.8 mm. The Combi 077-C de-airing extruder is designed for an hourly production rate of 70 t wet material.

In the first stage, the preparation line can therefore cover the total ceramic body demand of the entire plant production in one seven-hour shift, including an additional back-up margin of over 25%.

Ennadjah plant

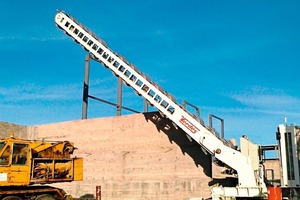

Storage management is completely automated thanks to the Verdés excavator with a hydraulic boom measuring 17.1 m in length, which will initially supply one shaping line, although, in a second stage it will be able to regularly supply two independent shaping lines. This equipment can work on a stockpile with a slope up to 30º, offering a filling section of 175 m².

The shaping line is big enough to achieve an output of over 175 000 t/year fired product. The line starts with a box feeder and a hinged roller mill with a roller diameter of 1 200 mm for refining the clay. Then the material is moistened again in the double-shaft mixer, model 046- C, before entering the de-airing combi-extruder, model 077- C. A dust collector is also included in the supply.

Conclusion

Thanks to its over 30 years of work in Algeria, Verdés has become firmly established on the Algerian market. To be close to its customers, Verdés has its own office located in Bordj el Bahri and ensures full after-sales service with immediate response together with the supply of spare parts from its 700-m² warehouse space.