Multifunctional processing equipment – Händle’s new line of double-shaft screen mixers

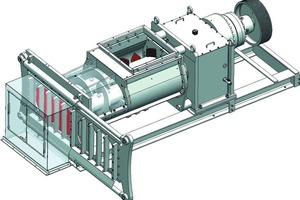

Originally, the double-shaft screen mixer was engineered with stone-elimination in mind, but then it met with great success as a multifunctional system for mixing, moistening, steam-heating, kneading, homogenizing, shredding and separating. To make optimal use of this material preparation capacity, Händle designed a pair of task-adapted types of double-shaft screen mixers, each in two different sizes: MDSG models with hydraulic screen shifting function for raw materials containing stones, wood, roots, grass, reed, plastic, etc., and lower-priced MDG models with a stationary screen for raw materials containing little or no contamination. Both types, though, operate on the same principle: First, the different raw materials are mixed together in the open mixing trough (mixing zone), where water, steam and/or additives are blended in as necessary. Then, the batch enters the closed double cylinder with two intermeshing augers (pressure zone) for intensive kneading and homogenization. Next, the thusly compacted body is pressed through a large screen, and the resultant shredding effect enhances the degree of preparation. The design principle of the overhung mixing shafts enables use of a large-area screen with a perforation pattern to match the envisaged throughput and desired shredding effect. The screen holds back the contaminants, which, in an MDSG-type mixer, drop into a holding chamber behind the screen. This type of mixer is characterized by a hydraulic screen frame with two screens, one upstream of the screen head and one situated at the ready outside of the cleaning action. The screens can be switched during operation of the mixer, so no time is lost. While the screens are changing places, an automatic screen cleaner goes to work and frees up the soiled screen, while the material that has collected in the holding chamber is stripped off into a takeaway container standing underneath. The screens of MDG models are cleaned by hand as necessary with the machine at a standstill, expediently at the end of each shift. All this requires is to disengage the fixing screws and swing open the hinged screen frame.

In addition to a clean-up of the model portfolio, the drive assembly has also been given a thorough overhaul. Now, Händle makes the distributor stage in-house, and any standard type of gearing can now be adapted to serve as the p.t.o. gear, hence catering to each customer’s own specific standardization efforts.

With a Händle-built double-shaft screen mixer (www.haendle.com ), the user has a highly efficient, multifunctional preparation system at his finger tips.