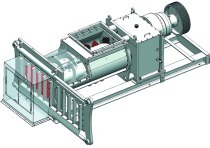

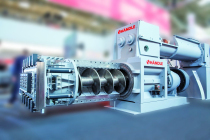

Better product quality with double-shaft screen mixers by Händle

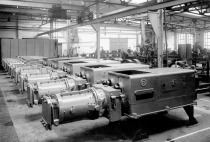

In Zi Brick and Tile Industry International 5/2014, Händle told the whole branch about the company‘s advanced series of double-shaft screen mixers. In the meantime, a number of them have been installed and some older-model Händle-brand screen mixers converted for service with finer mesh sizes. In any case, Händle is always prepared to implement schemes for installing new or used machines in existing facilities with limited space available.

In St. Andrae, Austria, for example, Brenner Brick Factory rigorously invests in its fabrication processes to guarantee brick production to the highest of standards. The plant‘s extraction area is partly wooded and studded with root remnants. Consequently, due to the thin webs (3 mm) of the company‘s Brenner S1 clay masonry units, such impurities in the clay had been stopping the dies, occasionally causing high reject rates.

Now, though, thanks to Brenner‘s new type-MDSG 1015e double-shaft screen mixer by Händle, with its 3 x 30 mm screen perforations, the number of rejects caused by clogged dies is near-zero.

Even for products that do not require such clean material, the emerging columns are showing more plasticity. The double-shaft screen mixer‘s throughput rate is 35 t/h or, for a speed of only 9.5 r.p.m., 19 m³/h.

The Händle double-shaft screen mixer series offers the following conspicuous advantages:

- high throughput, even with fine-mesh screens

- quick exchange of screens for different product requirements

- very good homogenizing and mixing effect (adjustable via paddle position and counter knives)

- low power consumption

- low wear-related costs

- low initial costs

Händle GmbH Maschinen und Anlagenbau

www.haendle.com