Fapro’s brick plant doubles its production capacity

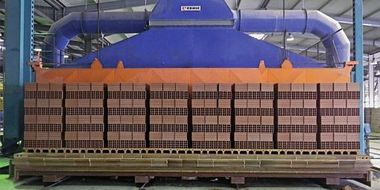

In 2009, Fapro, an Algerian company operating in the plastics industry, acquired a brick factory situated in the suburbs of Oran and contracted Ceric Technologies with its modernization in order to produce hollow bricks (10/20/30 and 15/20/30 sizes), which are the most popular brick sizes used on the very buoyant Algerian construction market. Just over a year ago, Fapro entrusted Ceric Technologies with the construction of a second sand-sealed Casing kiln to produce 294 t/day hollow bricks. Fapro also asked the French engineering firm to revamp the first Casing kiln built in 2009 by introducing all the necessary changes to increase its throughput capacity by 12% and achieve a daily production of 294 t/day or 100 000 t/year. The plant is now able to produce 200 000 t/year hollow bricks.

1 Introduction

The construction market in Algeria is booming. The entire heavy clay production is consumed by the domestic market. In accordance with the Five-Year Plan (2010 – 2014), more than one million homes and five new towns are to be built in Algeria. To meet the requirements of this housing improvement programme, Algerian brickmakers have been making large investments for some years now to ramp up the capacity production of their factories. As a result, the number of large production units has increased in Algeria. And it is not uncommon for current projects to involve production...