Block Brick Inspection System

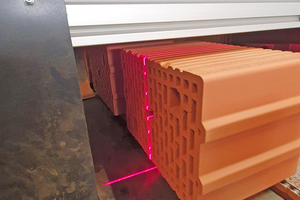

For checking the quality of clay bricks and blocks, especially their ground dimensions, ibea, a Hamburg-based company, supplies with a system comprising high-resolution colour-matrix- and 3D cameras. The Brick Block Inspection System (BBIS) is used to check all technically relevant sides of clay blocks.

Side-effects during grinding

In the production of clay blocks, the grinding station is very important as here the width dimension is set. During grinding, however, unwanted side-effects can result. For example, the sides may not be ground at right angles or with incorrect dimensions. As wear can be incurred during the grinding process, incorrect settings can also result during ongoing production. This can lead to off-spec products, which can only be filtered out of production with difficulty. Continuous monitoring would therefore be useful.

Ibea’s BBIS works with three high-resolution colour-matrix cameras and two 3D cameras with corresponding resolution mounted at the sides. The three colour cameras capture a matrix image simultaneously, after the two side-mounted 3D cameras have captured their image, says ibea, describing the operating principle of the system. The lighting for this is positioned in a light tunnel fitted with white LEDs. The lighting is provided with a flash. Thanks to the dome shape, all areas are homogeneously illuminated so that no important adjustments have to be made here. Only a one-time setting of the brightness is necessary.

Continuous monitoring with 3D cameras

The three matrix images in colour can be analysed simultaneously with dedicated software. For this purpose, in the three imaged surface planes, corresponding areas are set (surface planes = ROI), which are automatically checked with different algorithms. Depending on the setting, this is also used to identify the type of defect (called the classifier), that means specifying whether, for example, a hole, crack or chip has been detected. Homogeneous surfaces, on the other hand, are assessed to be free of defects by the BBIS. In the case of structured surfaces, the standard grooved profile can be masked out. This is done automatically. As the positioning is not always exactly the same during image capture, the inspection surfaces is centred or tracked based on the image. This is performed automatically for all sets of images.

The 3D images captured during the advance movement are captured with a delay, however, the results of the analysis are output with the results of the 2D image. The setting for the 3D inspection surfaces is performed as for the 2D inspected surfaces, however, as an algorithm, a check of the uniformity of the grid structure without interruptions is analysed. Other checks measure the distances of, for example, four corner points to each other. For this, the two 3D sensors are calibrated so the reading without a clay block would be “0”. During analysis, the trapezoid shape, ovality or rectangularity is calculated and compared with suitable presets.

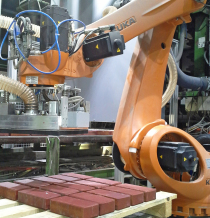

The collected data are logged to derive a trend and generate statistics, which can then be analysed over appropriate time periods. The system can be combined with a belt weigher, to determine the density of the clay blocks. This is also done automatically. Off-spec blocks can be removed by means of pneumatically operated ejectors out of the production line.

Conclusion

Ibea is convinced that BBIS is optimally suited for checking clay block quality, especially the ground dimensions. Thanks to the intuitive operation, a very easy set-up is possible. The system is suitable for continuous inspection of all products and very flexible in handling product changes, says the Hamburg-based company. Evaluation of the images is fully automatic and provides statistics with a detailed information on defects (classifier).