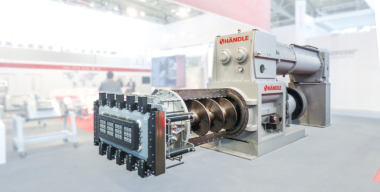

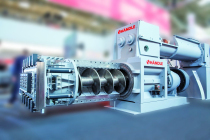

Developments in die engineering and wear technology

Top quality of replacement and wear parts is demonstrated in optimized wear behaviour, long lifetimes and simplified handling when replacement becomes necessary: characteristics that contribute to maximized availability of machines as well as minimized failure and downtime.

The subject of wear has always been a priority at Händle – research and development are not limited solely to new machines and processes. Replacement and wear parts are constantly further developed and adapted in accordance with the latest findings. At Händle, integral components for this are the practice-oriented applications laboratory, after-sales service as well as development and design. To advance the topic of wear in close cooperation with customers more effectively, a central office has been created at Händle for the primary coordination of tests, but also to work out and realize new possibilities in test set-up.

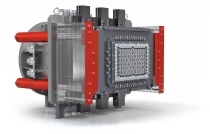

Dies for the extrusion of heavy clay ceramics are no exception here. The high pressures subject forming dies to extremely high and tribological stresses. The materials therefore have to exhibit properties such as high wear resistance and hardness as well as good sliding behaviour. At the same time, such materials must be easy to machine, enabling the production of complex geometries. With the introduction of new metallic materials, attempts are made to meet requirements for the lifetime of the tools and the quality of the products. In the talk, Händle and ZMB Braun are presenting the latest possibilities and projects.

Sebastian Mozer, Händle GmbH Maschinen und Anlagenbau

Michele Coluzzi, ZMB Braun GmbH