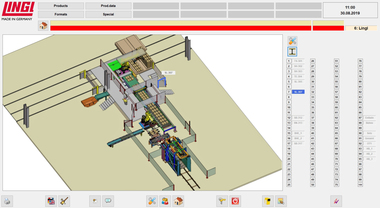

Digital Manufacturing Software

Here is a Sacmi-developed digital manufacturing software package that allows fully digital control of factory flows. With this software, Sacmi aims to provide its customers with all the benefits of a 4.0 approach to production. From ‘overview’ functions to integrated control of production flows, as stated by Sacmi, the software makes manufacturing better and faster by optimizing every stage of production and creating a new ecosystem that interlinks technology, people and processes.

The Italian company has configured Here as the link between the production environment and the ERP-System (Enterprise-Resource-Planning), letting manufacturers control all production-side data flows and optimize all-round factory control.

Link between ERP and MES

The key advantage of the system is its modularity, which lets customers take a gradual approach to digitalization and enjoy immediate, evident benefits. The first step involves the implementation of overview functions: these let users monitor, via a simple interface that can be consulted on fixed or mobile devices (smartphone, tablet), all essential plant data via the calculation of Key-Performance-Indicators and real-time identification of the causes of any problems.

The second step consists of upgrading the system to encompass actual MES Manufacturing-Execution-System functions – process control traceability, quality, energy analysis and maintenance management. In its most advanced configuration, Sacmi Here interfaces with the client’s ERP and calculates product requirements, optimizing the different stages of production via recipe management and advanced operational scheduling functions.

The systems goals are, according to Sacmi, to produce better, produce faster, reduce inefficiencies and automate the entire production flow: goals achieved thanks to a system that implements advanced MES functions and acts as the infrastructural link between the Information Technology and Operational Technology levels of the plant. Installable on either a physical or virtual server, the system gives customers excellent access control and has been designed according to strict cyber-security criteria.

Made-to-Measure Configurations

Sacmi aims to operate on the market not just as a provider of software and plant engineering solutions but also as an all-round plant digitalization partner, explained the Italian company. Provision of the Here solution always begins with a detailed analysis of the client’s needs, from case-specific configuration of production flows to the benefits the client wants from the system. That is why Sacmi, in addition to offering a modular approach to digital ceramic manufacturing, can also develop made-to-measure configurations that are indispensable when progressing from an overview approach to implementation of true MES functions.

First launched a few years ago, the software has since been installed by leading manufacturers worldwide and optimized on the basis of in-the-field-feedback. Key customer-confirmed advantages include, on the one hand, higher productivity and versatility, and optimized control of economic and environmental costs on the other.