Equipceramic completes upgrading of the dehacking line at Hermanos Díaz Redondo’s roofing tile factory

Goal of the investment was an improvement in product quality to step up the export of clay roofing tiles to other highly competitive markets. Hermanos Díaz Redondo contracted Equipceramic to implement a solution adapted to the operational needs and oriented to modern market requirements.

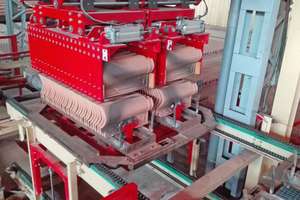

Equipceramic designed a fully automated solution based on robotics for removing wire from roofing tile initial packs, sorting and replacing them and arranging new rows with several strapped roofing tile packs.

Wire is automatically removed from packs on a rotary platform that turns two rows of roofing tiles 90º. A device consisting of four jaws grips and tightens the wire on the convex side of the row so it can be cut out by four cutting disks on the opposite side. Once the wire is released, it is pulled back by the jaws and collected in a container.

A gripper, which is mounted onto a frame with double row capacity and with a spacing mechanism, takes the two wire-free selected rows and delivers them to two manipulators, each one consisting of an inclined conveyor with stop pieces and a robot with a double gripper turning 90º. Roofing tiles are set into 4, 5 or 6-unit groups on the conveyors at the pack-strapping area by this gripper which is equipped with a device to push the rows closer together before they are collected.

The strapped roofing tile packs are always turned frontwards by means of a four-blade turning device. Each pack-making line is equipped with a pack-strapping machine and some space has been left for the installation of two additional pack-strapping machines in the future.

One of the key advantages offered by this installation is the possibility of making packs containing a variable number of roof tiles (between five and seven), so dispatch packs can be tailor-made, resulting in the most efficient use of the available space and therefore in significant savings in transport expenses.

The new equipment was designed so it was fully compatible with the equipment already existing in the plant and it could be comfortably integrated in the current production line. It has a production capacity of 7 500 roofing tiles/h. The new installation was completed in August 2016.

Equipceramic, S.A.

www.equipceramic.com