High-quality, energy-wise refractory systems for the brick and tile industries

in Spain and South America

1 Cerámica La Escandella SA

In early 2016, Cerámica La Escandella SA converted its roof tile firing technology from U-cassettes to the more advanced H-cassette system.

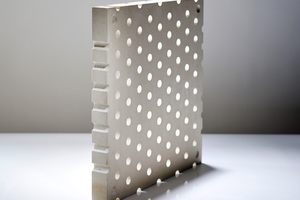

For this project, Refratechnik supplied the refractory superstructure for the tunnel kiln cars and 75 000 reversible cassettes. When roof tiles are fired in H-cassettes, each tile is loaded individually into a specially designed H-cassette to ensure that firing is homogeneous with no bending effects. Particularly for flat models, planarity is a decisive quality criterion, and horizontal firing in an H-cassette fulfils it better. Finishing in the form of a glaze or engobe calls for H-cassettes, because they minimize adhesion. In U-cassettes, where the roof tiles touch each other, such adhesion cannot always be avoided. The new H-cassettes are designed for reversibility and can therefore be used for eight different types of roof tiles.

In addition, Cerámica La Escandella is using innovative base frames to very substantially reduce spalling on H-cassettes. These cast frames for carrying stacks of H-cassettes are made of the same material as the cassettes, so they also have the same coefficient of thermal expansion. This produces less friction, since all of the material expands at the same rate.

2 Mazarrón Tejas

Mazarrón Tejas, too, has decided in favour of H-cassettes for firing roof tiles.

In this case, the conversion goes from “Laterforni” single-layer firing, where all cassettes occupied the same, single plane. Mazarrón is set to begin firing in H-cassettes this April or May. The kiln technology and machinery was supplied by plant contractors Marcheluzzo and Direxa. Refratechnik Ceramics supplied the refractory material for the roof/walls and 75 tunnel kiln cars. The refractory installations for this modern roof tile firing system are rounded out by 95 000 reversible cassettes. The tunnel kiln cars are equipped with Refratherm high-end insulation, a material that will help Mazarrón save decisive amounts of energy.

3 Tejas Borja S.A.U.

The introduction of H-cassettes in the production of Spanish roof tiles has now been fortified by the conversion project at Tejas Borja S.A.U.

The switch to H-cassettes has just been set out in writing. The conversion will be implemented in cooperation with the plant contractor Cleia SAS. The commission for the refractory lining of 61 tunnel kiln cars and 55000 reversible cassettes went to Refratechnik Ceramics. The plant is scheduled to go online in January 2018.

4 Success on the South American market

Refratechnik Ceramics also has been markedly ramping up its activities on the South American common market Mercosur.

Ceramica City SA, one of Brazil’s leading heavy clay producers, finds Refratechnik’s draught blocks very convincing, because they are of a whole different quality than the previous models. Ceramica City is seeking to secure routine resupply for that area. U-cassettes are presently being tested at Milano Rosso.

Refratechnik Ceramics is supplying the tunnel kiln car material for a modernization project at the Mazarrón backing brick plant in Paraguay. The Spanish company Physic GM is the engineering contractor responsible for this project.

Major projects in Peru include consignments to the Latercer Ladrillos Fortes brickyards, including kiln roof, kiln wall and tunnel kiln car material from Sabo and Refratechnik Ceramics.

On the Columbian market, the Casa Gres brickworks already received a supply of perforated slabs in 2015 that are still serving well despite exposure to temperatures up to 1 200 °C.

Refratechnik Ceramics GmbH

www.refra.com