Ibstock decides once again in favour of Keller HCW

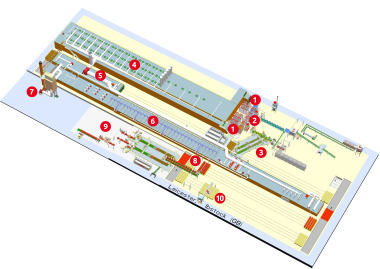

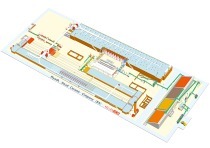

In 2015, Keller HCW received a fiercely contested contract from the Ibstock Group to build an ultramodern facing brick plant in the English village of Ibstock. Not only is it the third brick plant at this location for the UK‘s largest brick manufacturer – it is also the eighth plant supplied by Keller. The new plant, whose commissioning is scheduled for 2017, will produce approximately 100 million soft mud bricks per year.

The scope of the project for the renowned Laggenbeck-based manufacturer of machinery and plants starts downstream of the soft mud plant supplied by De Boer Machines Nederland B.V.

As Keller HCW area sales manager Peter Hinken emphasizes, the plant impresses, amongst other things, with its very low energy consumption requirements: “In Ibstock we shall build a tunnel dryer with slotted jet walls and integrated sand collecting and cleaning equipment. This is still relatively uncommon for soft mud installations; however, it facilitates optimal heat energy management.“

Another characteristic is the newest generation of control systems that will be implemented in the new Ibstock plant. The head of the automation technology department at Keller HCW, Dipl.-Ing. Reinhold Ungruhe comments: “At the new Ibstock factory we rely on the Siemens TIA portal in the high-end segment S7-1500 both for process control and for automation technology. With this, the new Ibstock plant will be one of the most modern brickworks worldwide.“