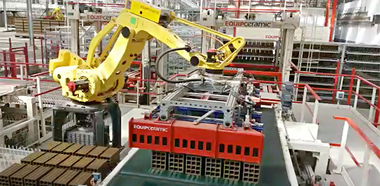

Ideal Brique automated by Sacmi-Cosmec

Sacmi Heavy Clay has won yet another strategically important order on the Tunisian market and this time it is all about process automation. Ideal Brique, one of the leading brick manufacturers in Tunisia, has purchased a fully automated plant that includes innovative automated cutting/stacking equipment and a dual-line unit for unloading the fired products, one of the biggest ever installed in Tunisia. It features automatic systems for the packaging and subsequent loading of completed brick packs onto trucks.

An integral part of a far-reaching plant renewal programme, this latest order for Ideal Brique includes, more specifically, an innovative complete pre-cutting and cutting line equipped with a dual unit for the deep-cutting, eliminating the need for subsequent trimming. The line processes and groups the dry products and includes a complete six-head stacker. The currently installed robots, which will be employed on the existing production lines, have been fitted with new grippers to solve the current product handling and picking problems. In addition to the four existing fired-product pack types (900 x 900 mm, 1200 x 1200 mm, 900 x 1200 mm and 1200 x 900 mm, in both Algerian and Tunisian versions), three different floor blockwork pack configurations (vertically perforated blocks, horizontally perforated blocks, mixed packs) are taken up.

The entire kiln – equipped with a Sacmi heavy fuel oil combustion system – has also been enhanced with new solutions such as the ground-level handling systems and conveyor belts and a kiln car pool that features cutting-edge refractory solutions designed to provide energy savings. Completing the picture, from a process automation standpoint, is the automatic bay stocking and truck loading system.

Beni Hassen’s company has always been very interested in innovation and has now chosen an all-new automation technology that is a first for Tunisia. The goal of the brick manufacturer is to become a pivotal player in revolution of the heavy clay production processes in Tunisia.

Sacmi Imola S.c.r.l.

www.sacmiheavyclay.com