Morte supplies Petrokeramika

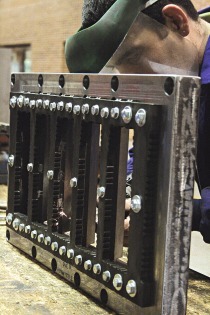

The TM-EF die chosen for the production of the backing bricks with two exits and 33 cores features three casings (the latter with inner steel lining), a treated steel exit and brakes regulated outside the die.

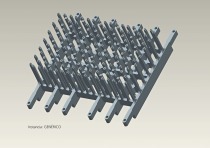

The die to produce the thermal blocks (551 x 285 mm) with 143 cores was also manufactured based on the TM-EF concept and features an inner steel lining, a treated steel exit and regulated brakes.

The die for facing bricks (exit: 267 x 129 mm) with 18 cores was achieved using a TM-EF model, featuring three casings with inner steel lining, a treated steel exit and external brakes.

The TM-N die was chosen for the pavers (267 x 129 mm), this features two casings (the latter protected internally by a treated steel sleeve) and a treated steel exit and entry on the corners.

All the dies are based on a modular design so that all parts can be easily replaced. A core holder fixing system ensures the necessary stability during extrusion. This prevents rotation and movement between the cores and ensures the required shape and size of the extruded product.

The use of anti-wear materials is another key factor in these dies – particularly for pieces with complex geometry and thin walls as in the case of the thermal blocks.

The die casings have been reinforced with inner steel, lengthening the lifetime of the die and improving the quality of the products.

Petrokeramika CEO Sergei Petrov has highlighted that the dies “are very straightforward as regards maintenance”. The quality of the dies has convinced and Morte’s technical service impressed him: “When the core holder needed changing, the service was both swift and high quality.” Technicians from Morte visited Petrokeramika in June 2013 to undertake the start-up.