Morte expands its business in Europe, Asia and America

Romania

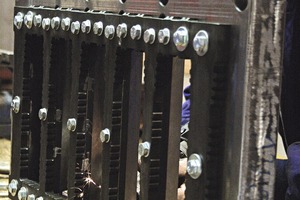

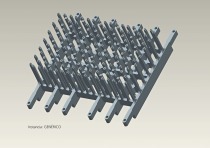

Brikston, one of the leading companies in Romania, has specialized in the development and production of bricks and blocks with good compressive strength and thermal conductivity. Last October Morte supplied dies for new products that Brikston would like to launch onto the market: three lattice dies (374 x 197 mm) with different output configurations (the arrangement and shape of the cores varies) and a three-output bottle rack die. All the dies have been developed from Morte’s TM-N model, with the outer plate being protected by means of a heat-treated steel sleeve, which gives the die a longer life and improves the quality of the extruded products. The output (cores and frames) is made of heat-treated steel and the core holder is made of alloy steel.

Also in October, Morte supplied Cemacon with a two-output die to improve the extrusion process. The TM-EF model is used for the manufacture of masonry blocks with good thermal insulation (size 301 x 254 mm) and has 67 cores per output. This die is aimed at the “green building” concept: in Romania Cemacon has developed the only block that requires no additional insulation and the company is a partner of Green Romania, an organization that advocates energy efficiency of buildings and responsibility towards the environment. The die has been designed with three casings, the last one protected with inner steel, heat-treated steel output with anti-rotation system and external regulation by means of brakes.

Iraq

Panama and Cuba

Orders were placed by El Tejar de Managua, a red brick factory in Cuba to which Morte supplied two model TM-N dies in last July, one of them 208 x 135 mm with two outputs and the other one 208 x 104 mm with four outputs. Both dies are internally protected by means of a heat-treated steel sleeve, and the output is made of the same material. Spare parts were supplied along with the dies in order to extend their lifetime.

In July, Morte also supplied Procesadora de Arcillas, S.A. (Panama) with two TM-EF dies in order to manufacture new products in the country: one 480 x 107 mm block with 37 cores and another 480 x160 mm block with 43 cores. Both dies consist of three casings, the last one protected with inner steel, with heat-treated steel output and external regulation by means of brakes. After performing tests and checking the proper operation of the dies, the company asked for the output to be replaced with hard metal and for the core holders to be delivered with hard chrome plating for both dies. Procesadora de Arcillas, S.A. manufactures and distributes products such as horizontally and vertically perforated blocks, clay pavers, Imperial tiles, accessories and special products.