New gas analyser for continuous selective determination of sulphur dioxide,

ulphur trioxide and hydrogen chloride

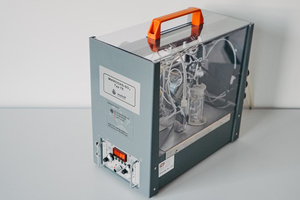

Fuel-related and raw material-related corrosive gases such as sulphur dioxide (SO2), sulphur trioxide (SO3) and hydrogen chloride (HCI) contained in the exhaust gas of kiln can be analysed continuously thanks to the Microgas TE analyser of Wösthoff Messtechnik GmbH based in Bochum/Germany, funded by EuroNorm GmbH. The Technical Instructions on Air Quality Control (TA-Luft), among others, stipulate the compliance with emission limit values of these gaseous, inorganic substances to provide precautions against harmful effects on the environment. These requirements apply to all installations approved in Germany, unless otherwise specific arrangements have been made for the system type. The new analyser allows the operator to determine, in a continuous, wet chemical process, both sulphur oxides and hydrogen chloride contained in the exhaust gas of a laboratory kiln as well as in the flue gas of the brickworks during the firing of bricks.

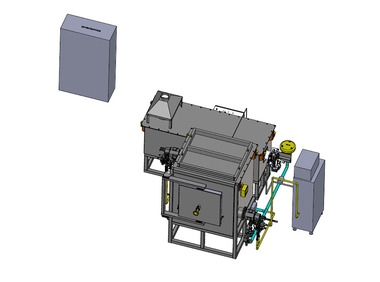

Test specimens especially produced or small pieces of the unfired original product are used in a laboratory test. The gases emitted during the firing process are sucked from a wet extraction head along with an absorption solution to the electrode measuring section of the measuring cell using a hose pump. In this step, the sucked in sulphur dioxide, for example, reacts with the hydrogen peroxide contained in the test solution to form sulphuric acid. The change in conductivity caused by the sulphur acid and/or hydrochloric acid occurring in this process is a measure of the concentration of sulphur dioxide, sulphur trioxide and hydrogen chloride contained in the test gas. The sucked in sample gas is separated from the absorption solution before the electrode measuring section.

Changes in the firing process are detected immediately

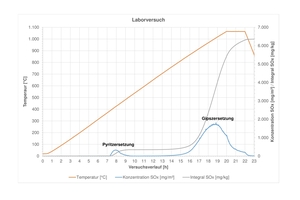

Due to a continuous measurement and the attributable firing curve, the occurring emissions can be directly assigned to the temperature range where they occur. In this way, detailed information can be analysed about the occurring corrosive gases. Figure 2 illustrates the results of the sulphur oxide concentration of the test specimen measured in the laboratory as an example. The orange curve indicates the temperature profile of the specimen. The blue curve indicates the escaping amounts of sulphur oxide in mg/m³. At first, the continuous analysis shows the pyrite decay with a small peak in the range of lower temperatures, before the decomposition of gypsum subsequently begins at above 800 °C. The grey curve indicates the sum of the emitted sulphur oxide concentration in mg/kg of specimen weight. A continuous measurement of hydrogen chloride is also possible.

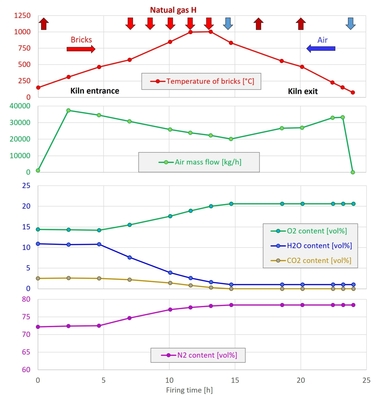

In addition, the Microgas TE analyser provides the opportunity of measuring the corrosive gas in the brickworks directly (large-scale test) so that various changes in the firing process and their effects on the exhaust gas emissions can be detected immediately. Thus, for example, the effects of a changed production capacity or modified raw material mixtures on the exhaust gas emissions can be analysed in a fast and detailed way. The mobility of the device not only allows an analysis in the laboratory but also at the brickworks without any problems and even at different measuring points.