Predictive maintenance reduces downtimes and maintenance costs

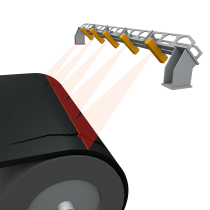

More serious damage such as longitudinal slitting or splice faults on the conveyor belt can have serious consequences for system operation, and lead to total failures in a worst-case scenario. The monitoring system Conti MultiProtect helps to detect such damage at an early stage during operation and repair the damage in good time. This helps to avoid extended downtimes. The way it works is that rip inserts implanted into the conveyor belt are checked for longitudinal slitting based on their characteristic magnetic fields. Using RFID (radio-frequency identification) chips, ContiTech has been able to optimize localization of longitudinal slitting on the belt. Conti MultiProtect is also able to monitor the condition of the joints and identify damaged spots within the carcass. The user-friendly system has an intuitive operating design that uses a graphical interface.

This permanent monitoring gives a detailed picture of the condition of the conveyor belts at all times without having to interrupt operations. This allows cover repairs to be scheduled preventively in good time, thereby reducing maintenance costs. ContiTech uses software developed in house.

ContiTech AG

www.contitech.de