Surface scanner from ContiTech makes conveyor belt damage visible

Conti Inspect systems

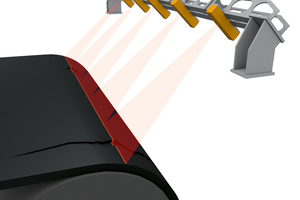

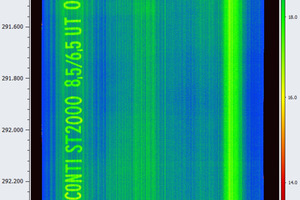

To help customers with servicing, ContiTech has developed the mobile inspection system Conti SurfaceInspect. Using ultra-modern line laser technology, this system scans the entire conveyor belt surface and creates a digital belt map on which all cover plate damage is recorded and can therefore be examined more closely. In an automatically generated report, all relevant information about the damage is provided.

These analyses result in a detailed picture of the condition of the conveyor belt surface. It offers an ideal basis for systematically recording surface damage, preparing cover plate repairs, and making predictions about the conveyor belt‘s service life.

The offering is rounded off by two further Conti Inspect systems. By means of triangulation sensors, Conti WearInspect measures the cover plate thickness over the entire belt length. It records the position of the belt surface on the pulley and carrying side, and calculates the conveyor belt‘s actual thickness by means of a large number of measuring points. It even detects systematic wear. This means that the conveyor belt‘s service life can be estimated, and a belt change recommended if necessary.

If damage occurs inside the carcass of the steel cord conveyor belt, it can be detected with Conti CordInspect. By means of magnetic induction procedures, it detects the smallest damage to the steel cable tension members. All incidents of damage are detected, classified, and documented in a report with information about size, severity, and position.

Conti Protect: providing protection from total failure

Larger pieces of damage such as longitudinal slitting and splice faults on the conveyor belt can have serious consequences for system operation. Conti Protect monitoring systems help to detect such damage at an early stage during operation, and automatically stop the system if necessary.

Conti SpliceProtect monitors the length and stretch of the conveyor belt splices in systems that are exposed to heavy tensile forces due to long centre distances or large height differences. The system uses magnetic strips vulcanized into the conveyor belt to make precise measurements during operation. As soon as a splice has reached a critical length, the danger of a splice failure becomes too great and the system stops the conveyor before the splice tears.

Conti RipProtect provides protection against longitudinal slitting. Thanks to conductor loops vulcanized into the conveyor belt, it detects the dangerous longitudinal slitting at an early stage. The metal loops carry a high-frequency signal between a transmitter and receiver. If a loop is damaged, the signal will break down on the receiver end. The system control then automatically stops the conveyor belt.

Conti CordProtect allows customers to look inside the carcass of steel cord conveyor belts. The system magnetizes the tensile members and detects magnetic fields that arise at the ends of the cords or if defects occur. This means that even very minor cord damage in the intact belt area can be detected and monitored, as can the state of the splices.

Conti MultiProtect expands the functions of Conti CordProtect. Rip inserts implanted into the conveyor belt are checked for longitudinal slitting based on their characteristic magnetic fields. By means of a special sensor application, the rip insert function can also monitor the rotation of tube conveyors.

Conti TotalProtect makes a detailed examination of steel cord conveyor belts possible by means of X-ray technology. The system detects and monitors all types of defects, from the tiniest pieces of surface damage and all manner of effects caused by foreign bodies, right up to cord and splice damage.