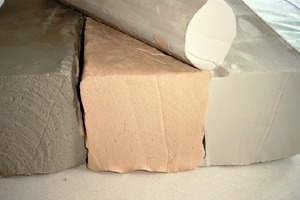

Primary and secondary raw materials from Witgert

Ever since 1820, the Arno Witgert Company has been mining high-quality clay in the Westerwald region. As early as the mid-20th century, the company began to refine the raw materials by comminution, and is now supplying clays and bodies by all means of delivery and for all ranges of application. The company also strategically procures, secures and markets secondary raw materials for the ceramic industry. These include grog from all types of ceramic cullet, e.g., clinker bricks, tiles (wall, floor, roof) and scraps of sanitary ware, as well as high-alumina porcelain deriving from broken insulators, mullite from broken kiln rollers, light grog from broken lightweight refractory bricks and cordierite from broken kiln furniture. Clayey raw materials occur as by-product in the mining of sand and gravel, coal and other types of rock, as well as in the form of filter cake in the preparation of such raw materials. Also filter cake stemming from the treatment of wastewater in the sanitary industry is marketed as valuable raw material for producing tiles and engineering bricks. Aluminium oxides and corundum filter dust with Al2O3 contents > 90% serve as raw materials for refractory products. Boron glass from hospital waste is finely comminuted for use as a low-cost substitute for frit.

Hall A1, Stand 509